Specialize in Compression molds

Specialize in Compression molds

Can you mold carbon fiber? Yes, you can freely mold the carbon fiber parts you want. For bicycle enthusiasts, carbon fiber bike frames tend to be lighter and stronger. So how to use the carbon fiber mold made by yourself to produce a unique carbon fiber bicycle frame?

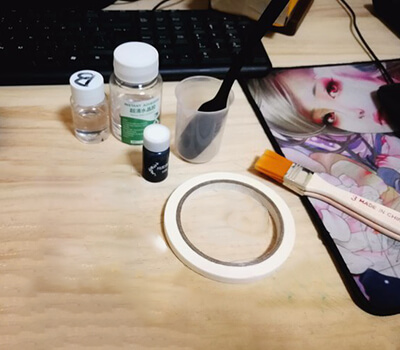

1. Prepare carbon fiber cloth, epoxy resin, knife, file, high-density plastic foam, sandpaper, scissors, and other materials.

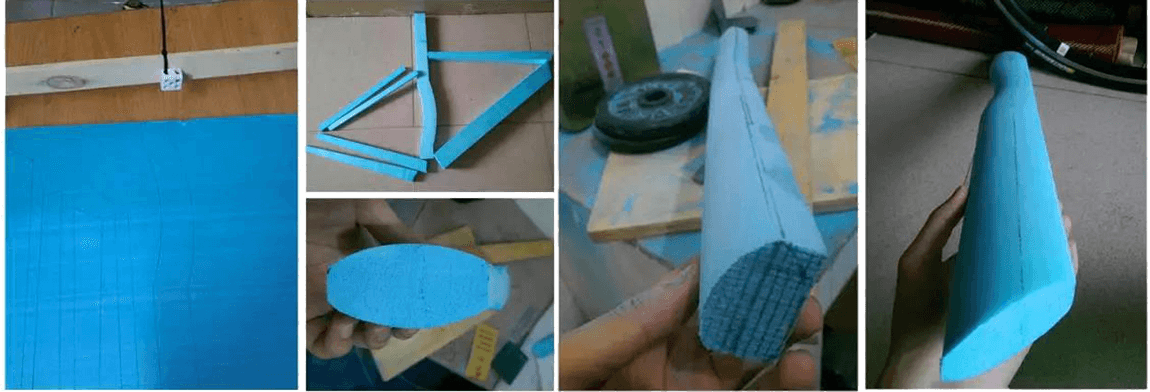

2. Plastic foam is used as a carbon fiber mold. Use a sharp knife to slowly cut the foam into the shape of the frame. Remember to slow down when cutting, not too deep, to shape the basic shape. Patience is most needed here, and the quality of the mold directly affects the frame. You can also use wood, clay, pipes, etc. as molds. In general, foam is easier to process.

3. After that, it is the polishing step. Grind it roughly with a file first, then sand it finely with sandpaper. Wash and dry the mold after polishing

4. Cut the carbon fiber cloth according to the size of the mold. You can cut it slightly larger than the parts. If you are not using prepreg, you need to impregnate with epoxy resin.

5. Then the most important step is to stick carbon fiber cloth. After brushing the resin on the mold, wrap the carbon fiber cloth cut in advance when the resin is still sticky. Each layer of carbon fiber cloth must wait for a layer to dry before sticking. The carbon fiber layer should be tight, and the carbon fiber cloth should not be deformed as much as possible. At the same time, it should be wound as slowly as possible, so that the internal air can be discharged. After the winding is completed, fix it with electrical tape and tear it off after molding. You can freely choose the number of layers of carbon fiber in places where reinforcement is required. Of course, if you have a vacuum bag, this process will be completed more quickly and perfectly. You can apply some heat to the carbon fiber parts to help them cure more quickly. Of course, it can be fully cured at room temperature, but it takes more time.

6. In the end, you still need to polish. Use a file to rub off the excess carbon fiber cloth on the edge, then use rough sandpaper to polish the edge, and finally polish the entire part. Carbon fiber powder is extremely harmful to the human respiratory system. It is easy to be allergic after contact with the skin, so you need to pay attention to your safety.

Not just bicycle frames, all carbon fiber molding methods are similar. If you want to produce carbon fiber parts in large quantities, you need carbon fiber molds manufactured by MDC Mould. Carbon fiber molds, usually made of strong metal, can withstand repeated use and maintain good surface finish and dimensional accuracy.

Contact US

Email: master@zjmdc.com

Tel: +86 576 84616076

Fax: +86 576 84616079

Mobile: +86 13906573507(Mr. Wang)

Address: No.116 mochuang road, Huangyan Xinqian street,Taizhou,Zhejiang,China