Specialize in Compression molds

Specialize in Compression molds

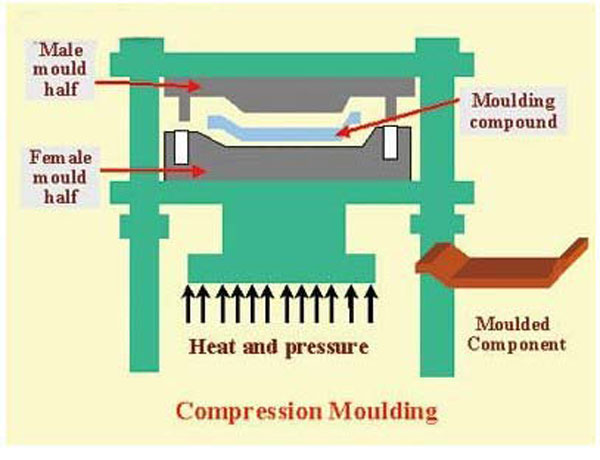

Compression molding process is based on the characteristics of each stage of the curing reaction of thermosetting plastics or other moulding materials.

Compression mold uses a hydraulic press in which a mold is fixed on the top and bottom platens of the press. The molds can be classified as hand molds, used for trial runs; semiautomatic, in which the press follows a programmed cycle but the operator manually loads and unloads the press, and automatic, which operate under a fully automatic press cycle (including automatic loading and unloading).

The process of compression molding is as follows:

The difference with the injection mold is that the compression mold has no pouring system, and the mold is equipped with a feeding chamber. There is a heating device in the cavity or feeding chamber. The structure of the compression mold can be divided into the following major parts.

(1) Cavity part. The cavity is the location where the part is directly formed, where the mold cavity is composed of a punch, a core, and a cavity.

(2) The feeding chamber is different from the injection mold. There is a feeding chamber containing raw materials above the compression mold cavity.

(3) Heating and cooling system. Thermosetting plastic compression molding needs to be performed at a higher temperature, so the mold must be heated.

In addition, like the injection mold, the compression mold is usually also provided with a guide mechanism, a demoulding mechanism, a lateral split core pulling mechanism, etc., which will not be repeated here.

There are different types of compression molds in the market, they may have different names due to different compression molding materials, such as SMC mold, BMC mold, GMT mold, LFT mold, but more often they are classified according to the compression mold structure.

When designing compression mould, it is necessary to design the cavity according to the size and moulding method of the product, besides, it is also required to select the appropriate steel according to the quality requirements and demand of the product surface. Compression mould should be made of mould steel with easy cutting, compact structure and good polishing properties. Such as: P20, 718, 1.2738 (adjust freely), etc. In addition, it is necessary to consider the related problems of machining accuracy and control the dimensional tolerance, shape tolerance and surface roughness

In order to improve the wear resistance and corrosion resistance of compression mould surface, surface treatment is usually carried out. Chromium plating is one of the most common methods. Chromium plating can keep metallic luster for a long time, and it is stable in various acidic media without chemical reaction. Chromium plating has excellent wear resistance and high heat resistance. When the temperature reach to 500℃, there is no obvious change of its appearance and hardness. In addition, nitriding treatment can greatly improve wear resistance.

The parting line design of compression mould should be easy to demoulding, and the way of simplifying the ejection mechanism can be adopted. When the radial dimension of the product requires high precision, the influence of flash thickness on the dimensional accuracy of compression products should be considered, and the vertical parting line can easily ensure the dimensional accuracy of the product

Compression mould temperature directly affects product quality and production efficiency, and the temperature design of compression mould is usually between 140℃ and 160℃. Heating system includes electric heating, steam heating and oil heating. When designing the temperature system of the mould, choosing the appropriate heating method and ensuring the uniform surface temperature of the mould can reduce the deformation and improve the dimensional stability.

In compression mould design stage, new mould software (CAD/CAM, etc.) is used to master the whole process of compression mould design, manufacturing, assembly, inspection, testing and production, including mould design and manufacturing cost estimation, mould assembly evaluation, mould parts manufacturing process evaluation, mould structure and formability evaluation.

The steel used for compression molds is alloy steel, carbon steel. Alloy steel is a high alloy steel with very low carbon content and is therefore very tough. Carbon steel contains more carbon than alloy steel and is less hard, but is also cheaper than alloy steel. The most common steel used in compression molds is alloy steel. This is because the mold needs to be able to withstand the pressure of molten metal and low alloy steels can withstand higher temperatures than carbon steels.

MDC mold steel suppliers are ASSAB, BUDERUS, LKM, AUBERT&DUVAL, DAIDO, FINKL, HITACHI, ALCOA, BOHLER, SAARS TAHL, BAOSTEEL, etc. In addition to quality steel suppliers, we also use the best heat treatment process, and milling capability to meet the requirements of high precision compression mold. MDC controls the flash within an ideal range through CNC processing technology and the processing technology of mold steel to reduce the waste of materials as much as possible.

Compression mold may not be cheap, but it's not as expensive as you might think. But when you need to make a large number of parts quickly and economically, compression mold can be cost effective. This is because it requires less material, less energy, less labor, less equipment, and less overall resources.

Since 1997, MDC Mould have been designed and manufactured for compression moulding of SMC, BMC and GMT materials. Since then, the great achievement can be used to produce automobile moulds (bumper mould, front panel mould, top panel mould, bottom cover mould, pickup box mould, foot plate mould), bathroom moulds (shower base mould, sink mould, washing tank) mould, bathtub mould), electronic mould (meter box mould, connecting box mould, enclouse mould). After effective optimization, the compression mould we produce has a longer mould life and higher precision of product.

Contact US

Email: master@zjmdc.com

Tel: +86 576 84616076

Fax: +86 576 84616079

Mobile: +86 13906573507(Mr. Wang)

Address: No.116 mochuang road, Huangyan Xinqian street,Taizhou,Zhejiang,China