Specialize in Compression molds

Specialize in Compression molds

GMT is Glass Mat Reinforced Thermoplastics, a kind of sheet molding compound with fiber reinforced thermoplastic. It is produced on huge laminators, using a thermoplastic resin and one or more forms of reinforcement. The process yields a lightweight, consolidated, semifinished composite in sheet form. Most forms are produced to 1,300 mm to 1,400 mm widths. But, some newer forms are made to greater but proprietary widths. The sheet stock may be cut to size to suit placement in the tool for a specific application and also can incorporate a decorative or functional surface laminated to one side.

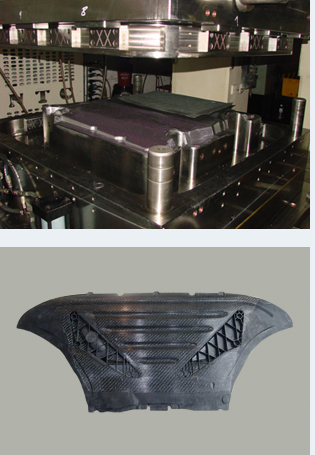

GMT mold is a cavity tool with a certain shape and size. It is used in conjunction with various systems or auxiliary mechanisms in the mold to produce a specific shape, Size, function and quality of GMT parts. GMT mould makes possible the production of large parts with low tooling costs and fast cycle times via compression molding. The potential for parts consolidation presents the opportunity to further reduce weight and cost.

What’s the advantage of GMT moulding parts?

- Use of regenerated、Low forming pressure、Long storage period、Short shaping cycle、High production efficiency

What’s the mostly application of GMT mold?

-

GMT mold is mostly used in Automotive and building&construction, chemical industry, packaging, sport equipment, etc.

What's the GMT tooling process?

-

When gmt mold is made, preheated gmt material will be puted on the center(cavity)between the top mold and bottom mold, pressing machine with 2500 Ton force make them into the finished products.

Compression molding of GMT mold is very similar to compression molding of SMC molding, with the only major difference being the type of raw material used in the process. In thermoplastic compression molding, GMT mold is used for making high-volume parts. This is the only thermoplastic manufacturing technique used in widespread commercial applications for making thermoplastic structural parts. The process of GMT mold is primarily used in the automotive industry. The Process of GMT mold is two to three times faster than compression molding of SMC tooling.

Contact US

Email: master@zjmdc.com

Tel: +86 576 84616076

Fax: +86 576 84616079

Mobile: +86 13906573507(Mr. Wang)

Address: No.116 mochuang road, Huangyan Xinqian street,Taizhou,Zhejiang,China