Specialize in Compression molds

Specialize in Compression molds

Traditional bathtub manufacturing materials are generally divided into three categories: fiberglass, steel and cast iron. The surface hardness of fiberglass bathtub is low, easy to scratch, poor wear resistance. Steel is a hard and durable material. Steel baths need to be covered with ceramic or enamel. Cast iron is very wear-resisting material, but the drawback of cast iron bath crock is heat preservation performance is poor, hot water can become cool very quickly. And the latest popular SMC (sheet mold plastic) composite bathtub can avoid the above defects.

To produce a high-quality bathtub, compression molding technology is very important. In addition, the moving speed of the slider of the press, the accuracy of the mold, etc. are also very high. The pressure, temperature, and even the pressure at the moment of opening and closing the mold must be very uniform and accurate. Products with a smaller area require less pressure, and products with a larger area, such as waterproof discs, wall panels, bathtubs, and roof panels, require a press with greater pressure. The pressure applied to the bathtub during molding is about 50 to 100 kg/cm2.

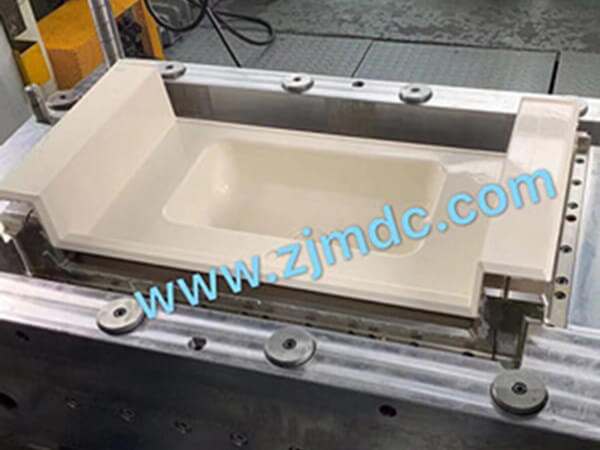

The compression bathtub mold generally includes two parts, a movable mold and a fixed mold (or convex mold and concave mold), and the two can be separated and closed. Take out the parts when they are separated, and inject the materials into the mold cavity when they are closed. SMC bathtub compression molds are precision mold products with complex shapes, which have high requirements on structural strength, stiffness, surface hardness, surface roughness, and processing accuracy.

The thickness of the SMC bathtub is 6mm. The molding technology adopts the compression molding method. The molding material of the bathtub is thermosetting SMC (sheet molding compound). The mold steel suitable for processing bathtubs includes ductile iron, forged steel, cast steel, pre-hardened steel, and normalized steel. When choosing the material of the mold, we must first consider the scale that the data can be processed, and then according to the specific conditions of the commodity, the strength, toughness, hardness, wear resistance, scale stability, machinability, weldability of the mold data, Polishability, data prices, to make the best choice.

Contact US

Email: master@zjmdc.com

Tel: +86 576 84616076

Fax: +86 576 84616079

Mobile: +86 13906573507(Mr. Wang)

Address: No.116 mochuang road, Huangyan Xinqian street,Taizhou,Zhejiang,China