Specialize in Compression molds

Specialize in Compression molds

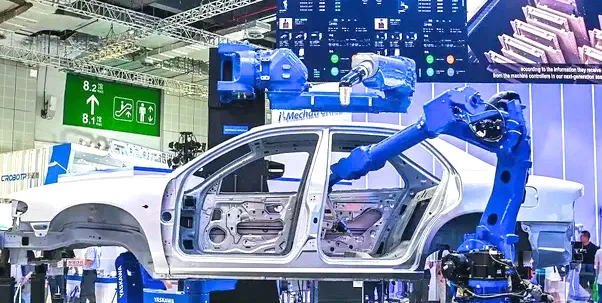

Under the rapid expansion of the global new energy vehicle (NEV) industry and the implementation of carbon neutrality and carbon peaking strategies, improving energy efficiency and driving range has become a core objective of automotive manufacturing upgrades.

Industry data shows that every 10% reduction in vehicle weight can reduce fuel consumption of internal combustion vehicles by 6–8%, while increasing electric vehicle driving range by 5–10%. As a result, automotive lightweighting has become a critical technical pathway to balance performance, efficiency, and sustainability.

Advanced composite materials are increasingly replacing traditional metallic materials due to their unique combination of high specific strength, low density, and design flexibility.

Common automotive composite materials include carbon fiber reinforced polymers (CFRP), glass fiber reinforced plastics (GFRP), and basalt fiber reinforced composites.

Compared with steel and aluminum alloys, composite materials typically offer:

In addition to weight reduction, composites provide excellent corrosion resistance, fatigue performance, vibration damping, and noise reduction, significantly lowering long-term maintenance costs.

In modern vehicle body design, composite materials are widely used in body frames, doors, hoods, tailgates, and roof structures. Through integrated molding processes, CFRP and GFRP components can achieve weight reductions of 35–50%.

Composite body structures also enable optimized aerodynamic designs, reducing driving resistance and improving overall energy efficiency. In several new energy vehicle platforms, the adoption of composite body structures has resulted in double-digit improvements in driving range.

Composite materials play a critical role in chassis and powertrain systems, particularly in suspension components, drive shafts, and structural reinforcements. Reducing unsprung mass improves vehicle handling, ride comfort, and energy utilization.

Carbon fiber composite drive shafts can reduce weight by more than 40% compared with steel alternatives, while improving power transmission efficiency by 5–8%.

For electric vehicles, EV battery enclosures represent one of the most important lightweighting targets. GFRP composite battery housings offer:

These composite solutions directly contribute to lower vehicle energy consumption and extended driving range.

Lightweight composite materials are increasingly applied to interior components such as seat frames, instrument panel carriers, and door inner panels. Typical weight reductions range from 25–40%.

Composite seat frames can be up to 50% lighter than steel frames, improving space utilization and vehicle packaging efficiency. Glass fiber reinforced thermoplastic instrument panel carriers also provide improved acoustic performance and vibration damping.

Continuous innovation in materials and processes is accelerating the large-scale adoption of composites in automotive manufacturing.

Key composite molding technologies include:

These technologies enable stable quality, high production efficiency, and cost-effective mass manufacturing for global automotive platforms.

Automotive lightweighting is closely linked to sustainability. Lighter vehicles consume less energy throughout their lifecycle, contributing to lower emissions and reduced environmental impact.

Emerging trends such as recyclable composites, bio-based resin systems, and digital process monitoring are further enhancing the sustainability of composite automotive manufacturing.

Composite materials have become the core enabler of automotive lightweighting, directly supporting energy efficiency improvements and extended driving range for both conventional and electric vehicles.

With continuous advances in composite molding technologies, compression molding tooling, and automotive composite applications, the automotive industry is accelerating toward lighter, more efficient, and more sustainable vehicle architectures.

Contact US

Email: master@zjmdc.com

Tel: +86 576 84616076

Fax: +86 576 84616079

Mobile: +86 13906573507(Mr. Wang)

Address: No.116 mochuang road, Huangyan Xinqian street,Taizhou,Zhejiang,China