Specialize in Compression molds

Specialize in Compression molds

A plastic compression molding machine (press) is the main equipment for molding thermosetting plastics, and is a machine that applies pressure to a compression mold. The earliest presses were hand-operated, which were labor-intensive and noisy, so they were eliminated. At present, presses are mainly motorized and hydraulic. The motorized press is driven by an electric motor, and the movable crossbeam is moved up and down by a gear screw device. Motorized presses are also gradually eliminated because they are more complicated to manufacture, maintain and operate than hydraulic presses, and they are not suitable for pressing large parts. Compared with other presses, hydraulic presses have the advantages of stepless adjustment of pressure and speed in a wide range, flexible movement, simple structure, low vibration and noise. Therefore, the plastic presses used at present are basically presses driven by hydraulics.

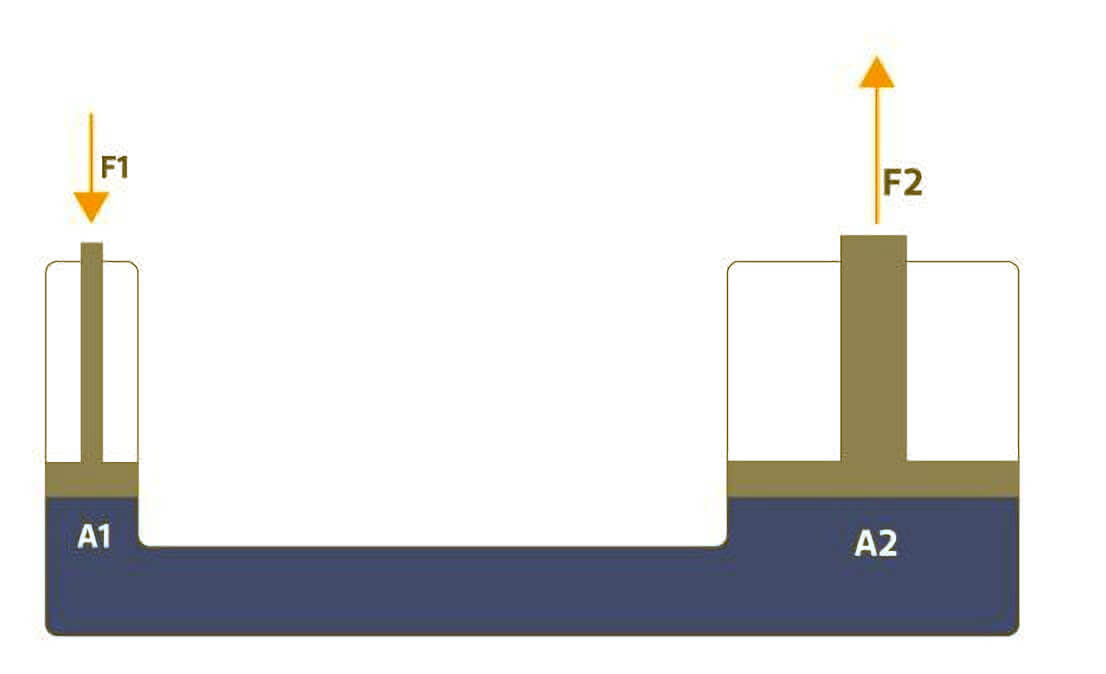

A hydraulic press is a device that uses a liquid medium to transmit pressure. Liquid in a closed container to transfer pressure follows Pascal's law: in a number of containers connected to each other and filled with liquid, if a certain place by the action of external pressure, the pressure will be transmitted through the liquid to each connector, the pressure value is equal everywhere. The small plunger in the hydraulic machine is the plunger in the hydraulic system, and the big plunger is the plunger in the working cylinder.

Plastic hydraulic press in the implementation of compression and transfer molding process to complete the mold closure, exhaust, mold opening and top action, as well as to provide the pressure required for molding.

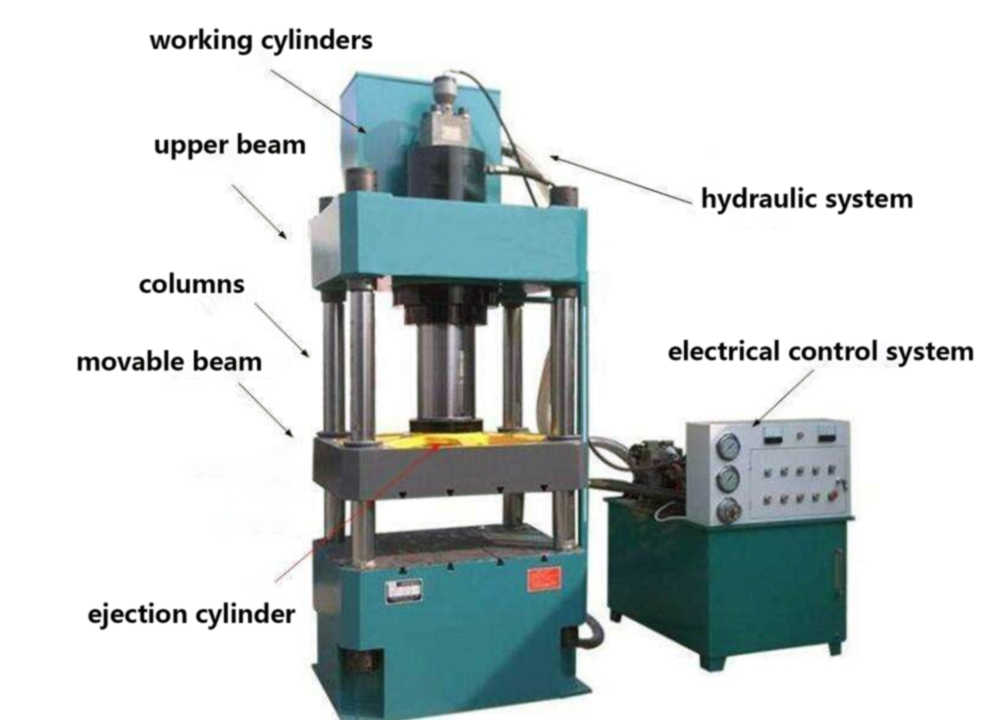

The basic structure of the plastic hydraulic press is mainly the body (including the upper and lower beams and columns, etc.), movable beams, working cylinders, ejector mechanism, hydraulic system and electrical control system and other parts. The working cylinder is installed on the upper beam. The movable beam is connected with the piston rod of the working cylinder as a whole, which can move up and down along the column (the frame hydraulic press is guided by the rail) and transmit the pressure of the cylinder to the compression mold.

The hydraulic drive system of hydraulic machine can be divided into power mechanism, control mechanism, actuator, auxiliary mechanism and working medium.

Power mechanism. Usually use the oil pump as the power mechanism, generally for the positive displacement oil pump. In order to meet the requirements of the actuator movement speed, choose an oil pump or multiple oil pumps.

Control mechanism. Its role is to control and regulate the pressure, flow and flow direction of the liquid medium to meet the action and performance requirements of the hydraulic system. Mainly using various forms of valves, such as directional control valves, flow control valves, pressure control valves, electro-hydraulic proportional valves and electro-hydraulic servo valves.

Actuator. Usually using various oil cylinders or oil motors. Such as the main cylinder that can provide molding pressure, the ejector cylinder for ejecting products and other auxiliary cylinders. Piston or plunger type cylinders are mostly used.

Auxiliary mechanism. Including oil tank, oil filter, pipes, joints, oil condenser, accumulator, pressure gauge, etc.

Working medium. Mainly hydraulic oil, its role is used for energy conversion and transfer, control of pressure and speed, etc.

There are many types of hydraulic presses, both mechanical and hydraulic, currently the common type is hydraulic, and most of them are hydraulic presses. Hydraulic presses can be classified in different ways, and the common classifications are as follows.

Frame type hydraulic press. The frame can be washed and cast as a whole or welded by section steel. Frame type hydraulic press is a small and medium-sized hydraulic press, used for pressing and forming of small and medium-sized pressing dies.

Column type hydraulic press. Generally, it is a medium and large hydraulic press, which is often used for pressing and molding of medium and large pressing dies.

Up-pressure hydraulic press. The hydraulic cylinder of this kind of hydraulic press is installed on the upper beam, and the piston is connected to the movable cross-dye to move up and down with the column as the guide, and the lower part is the fixed working table. It is easy to use and widely used for pressing small and medium-sized plastic parts.

Lower press type hydraulic press. The hydraulic cylinder of this type of hydraulic press is installed on the lower beam, and the piston is connected to the movable beam to move up and down with the column as the guide, and the upper part is a fixed working table. It is mainly used for pressing large parts, because of the inconvenience of operation, the use of less.

Manual control type wave press. The machine is completely operated by hand control.

Semi-automatic hydraulic press. Except for a few processes (such as adding materials and taking out products), other procedures related to pressure operation (such as pressurizing, holding pressure, releasing pressure, ejecting products, etc.) are carried out in an automatic manner.

Fully automatic hydraulic press. All procedures of pressure operation (including adding and taking out products) are carried out in an automatic way.

Hydraulic ejector type. The hydraulic cylinder is set under the table, and the screw hole on the end of the hydraulic ejector is used to connect the press mold push-out system when installing the tail shaft or intermediate joint.

Manual rack and pinion ejector. It is set under the lower table, and the screw hole on the end of the hydraulic ejector is used to connect to the press mold push-out system when the tail shaft or intermediate joint is installed.

Tie bar ejector. For the tie rod ejector form that uses the upper table of the hydraulic press to lift back, a tail shaft or intermediate joint can be screwed into the end face of the ejector rod.

There is also a downward pressed lower ejector type, a downward pressed upper ejector type, and an upward pressed lower ejector type.

MDC provides one-stop compression molding solutions to help you compression mold various thermoset composites including SMC, BMC, GMT, LFT. We will help you choose the most suitable press according to the molding process, and we also provide 4000T presses for large parts compression molding.

Contact US

Email: master@zjmdc.com

Tel: +86 576 84616076

Fax: +86 576 84616079

Mobile: +86 13906573507(Mr. Wang)

Address: No.116 mochuang road, Huangyan Xinqian street,Taizhou,Zhejiang,China