Specialize in Compression molds

Specialize in Compression molds

Recent studies, such as “Optimization Techniques in Compression Moulding: A Comprehensive Review” (Materials Science Forum, 2024), provide valuable insight into how process parameters, materials, and design strategies influence the quality and performance of molded composite parts. At Zhejiang MDC Mould Co., Ltd., these research findings are directly reflected in our development of advanced SMC and BMC molds for automotive, electrical, and construction industries.

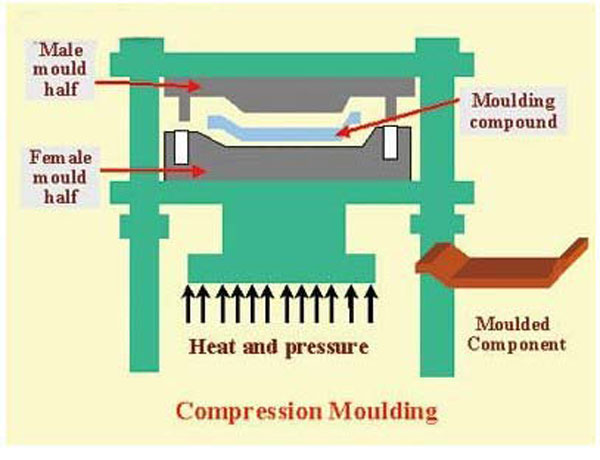

Compression moulding remains one of the most efficient methods for manufacturing high-strength, thermoset and thermoplastic composite components. However, parameters such as mould temperature, pressure, preheat time, and curing cycle have a significant impact on mechanical properties and surface quality. Improper control leads to defects like warpage, porosity, or uneven fiber orientation. Optimization therefore becomes essential — not only to enhance part quality, but also to minimize cycle time, material waste, and energy consumption.

The reviewed paper summarizes more than 25 studies on compression moulding optimization. The most influential parameters include:

Studies applying Taguchi methods and Response Surface Methodology (RSM) confirm that optimized combinations of these factors yield higher tensile and flexural strength while reducing shrinkage and surface defects.

The paper highlights several powerful optimization tools now used by leading manufacturers:

At MDC Mould, the optimization principles described in the study are applied to every project. Our engineering team integrates CAE simulation, thermal analysis, and digital process validation throughout the mold-making workflow. By simulating resin flow and heat transfer, we minimize trial iterations and ensure Class-A surface finish and dimensional accuracy from the first shot.

Furthermore, MDC applies a data-driven approach to balance heating zone control, cavity venting, and ejection systems. This guarantees stable cure cycles, reduced air entrapment, and improved surface gloss in large-scale SMC parts such as EV battery covers, truck panels, and water tank components.

Optimization is not only about performance — it also contributes to sustainability. Advanced compression tooling shortens cure times and lowers energy use per cycle. Optimized resin distribution reduces waste and extends mold life. These improvements align with MDC’s goal of building eco-efficient composite molding systems for global customers.

Looking ahead, MDC is exploring AI-assisted mold temperature control and real-time process monitoring. Combining sensor feedback with predictive models (inspired by RSM and ANN approaches) enables adaptive process correction during production — ensuring consistent quality even under varying material conditions.

Optimization research provides a strong scientific foundation for modern compression moulding. By integrating advanced algorithms and thermal simulation into tool design, MDC Mould continues to set new standards in SMC/BMC mold engineering. Every optimized parameter — from mold temperature to ejection force — translates directly into higher productivity, better surface finish, and longer tool lifespan.

For technical consultation or customized SMC compression mold design, contact our engineering team at www.zjmdc.com.

Contact US

Email: master@zjmdc.com

Tel: +86 576 84616076

Fax: +86 576 84616079

Mobile: +86 13906573507(Mr. Wang)

Address: No.116 mochuang road, Huangyan Xinqian street,Taizhou,Zhejiang,China