Specialize in Compression molds

Specialize in Compression molds

In the world of composite material molding, both Press Mold and Pre-Press Mold are essential but serve distinct purposes. Understanding their differences helps optimize production quality and efficiency in SMC, BMC, GMT, and D-LFT applications.

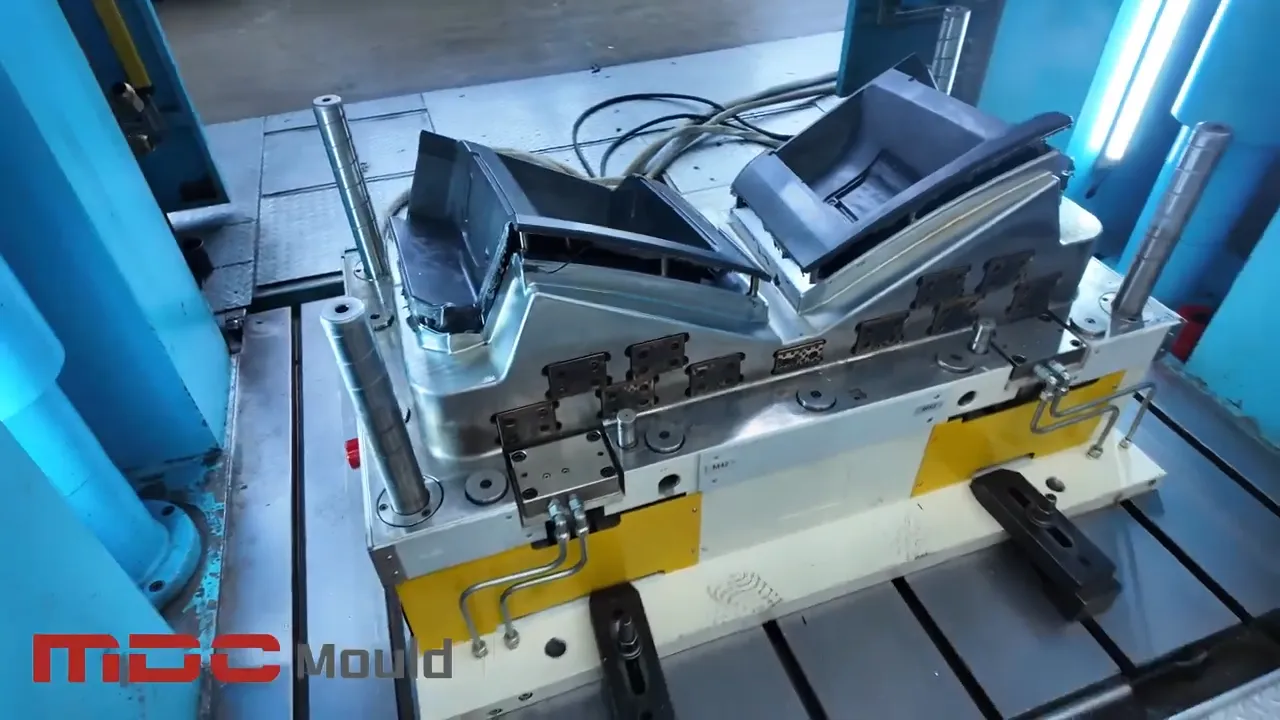

A Press Mold is the final tooling used in compression molding. It defines the final shape, surface finish, and structural performance of composite parts under high temperature and pressure.

A Pre-Press Mold is used to preform raw materials into a semi-finished shape before the final molding stage. It helps control thickness, fiber direction, and material consistency.

| Feature | Press Mold | Pre-Press Mold |

|---|---|---|

| Function | Final forming and curing | Pre-forming only |

| Temperature | High temperature | Room or low temperature |

| Production Stage | Final step | Initial step |

| Output | Finished part | Preform or blank |

| Complexity | Advanced mold with heating/ejection | Simpler mold |

MDC Mould provides comprehensive tooling solutions combining Pre-Press Molds and Press Molds:

Press Molds and Pre-Press Molds are not interchangeable but complementary. Understanding and applying them correctly enables better product quality, reduced waste, and higher manufacturing efficiency in composite part production.

Contact US

Email: master@zjmdc.com

Tel: +86 576 84616076

Fax: +86 576 84616079

Mobile: +86 13906573507(Mr. Wang)

Address: No.116 mochuang road, Huangyan Xinqian street,Taizhou,Zhejiang,China