Specialize in Compression molds

Specialize in Compression molds

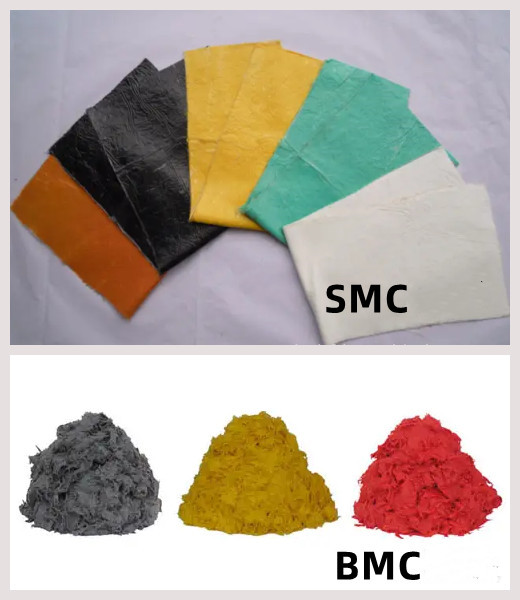

A compression mold is a specialized tool used in the compression molding process, a widely adopted manufacturing method for forming composite parts. It involves placing a preheated material, such as SMC (Sheet Molding Compound), BMC (Bulk Molding Compound), or other thermoset materials, into a heated mold cavity, then applying pressure to shape and cure the material.

Compression molds are essential in industries such as automotive, electrical, construction, and aerospace, where lightweight, high-strength, and heat-resistant components are needed.

A typical compression mold includes two main halves: the cavity and the core. It may also include:

Depending on the application, compression molds can be made from hardened steel, aluminum, or other high-strength alloys. Surface treatments like chrome plating may be applied to improve mold longevity and part release.

The compression molding process typically follows these steps:

This process is suitable for high-volume production of components with intricate geometries and excellent mechanical properties.

Compression molds are used to manufacture various thermoset and composite parts, including:

Thanks to their strength-to-weight ratio, compression-molded parts are replacing metal and thermoplastic components in many structural and semi-structural applications.

Using a compression mold offers several benefits:

For manufacturers seeking reliable and repeatable performance, compression molding with precision molds remains a top choice.

Both SMC molds and BMC molds are used in compression molding, but they differ slightly:

Choosing the right mold depends on the geometry, performance, and surface requirements of the final part.

A compression mold is an integral part of the composite molding industry. From automotive components to building materials, its role in shaping and curing high-performance parts makes it indispensable. With advancements in material science and precision tooling, compression molding continues to evolve and serve as a key process in modern manufacturing.

For companies looking to invest in SMC molds, BMC molds, or custom compression tooling, working with an experienced mold manufacturer is essential to ensure durability, precision, and production efficiency.

Contact US

Email: master@zjmdc.com

Tel: +86 576 84616076

Fax: +86 576 84616079

Mobile: +86 13906573507(Mr. Wang)

Address: No.116 mochuang road, Huangyan Xinqian street,Taizhou,Zhejiang,China