Specialize in Compression molds

Specialize in Compression molds

LFT-D is the abbreviation of Long Fiber Reinforce Thermoplastic In Direct Processing. This paper describes the process, product characteristics and applications of LFT-D technology for compression molding of long fiber reinforced thermoplastics.

Compared to GMT and LFT-G, which rely on semi-finished sheets or pellets, LFT-D is produced directly from polymer masterbatches and glass fibers on a daily basis, eliminating the intermediate process of sheeting or pelletizing. This reduces costs and makes it easier and more practical to select raw materials for the product.

Polymer pellets can be quickly adjusted and converted to meet product requirements and adverse conditions that occur during production. The fibers used for reinforcement can be varied in terms of formulation content and length according to the mechanical properties required. For some special physical properties and some special characteristics, such as thermal stability, flame retardancy, heat aging resistance, coloring, water absorption resistance, etc., the final product performance can be improved by directly adding other modification additives. The LFT-D process will result in a unique material formulation that can be adapted to the performance requirements of most parts for different product requirements.

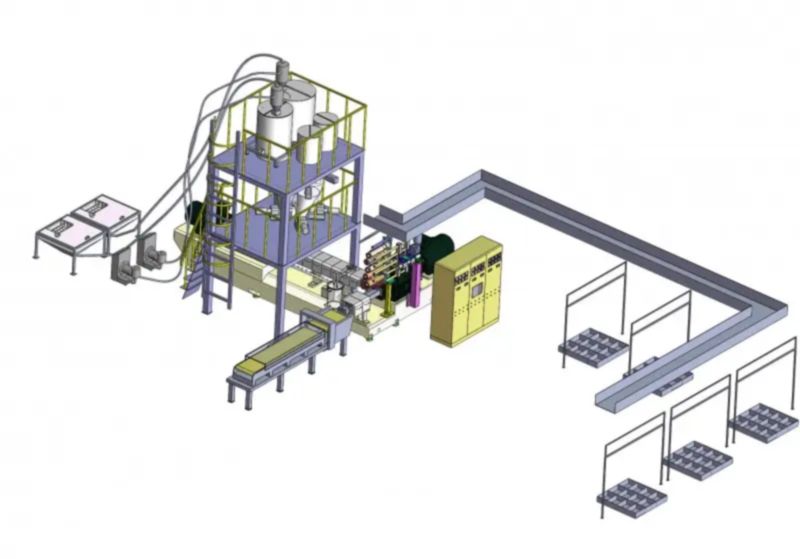

The typical LFT-D process is that polymer pellets and additives are fed into a dosing and feeding unit, which is initially programmed to ensure that the designed ratio of material is fed. The proportionally dosed feedstock is plasticized and mixed in a twin-screw extruder, where the molten polymer is passed through a film die to form a waterfall-like polymer film.

Glass fibers are introduced to the top of the polymer film through a specially designed yarn frame, preheated and dispersed, and then merge with the film into a second stage twin-screw extruder where the glass fibers are impregnated, cut and mixed to form a continuous block.

The cutting tool at the front end of the twin-screw glass fiber plastic mixing extruder cuts the block to meet the molding area of the product, and the conveyor belt transports it to the appropriate location, and then sends it into the mold for low-temperature molding, the whole process generally takes 30-50 seconds, which has great processing cost advantages compared to GMT molding.

At present, the main application area of LFT-D production technology is still automotive manufacturing. At present, the parts with more mature applications include bumper bracket, instrument panel skeleton, seat skeleton, underbody guard, interior trim parts bracket, wheel cover, battery tray, grocery box cover, rear liftback door, spare tire box, etc.

For example, underbody shield, which needs to meet the requirements of sound absorption, heat insulation, corrosion prevention, high rigidity, high impact strength, etc.. Initially, the manufacturing materials evolved from steel and aluminum to GMT, and now MDC has a lower cost and more flexible molding method, LFT-D technology. In addition, MDC Mould has started to use LWRT, a lightweight, high-strength thermoplastic with highly expanded fibers, which is less tough than traditional GMT but has high specific stiffness and excellent sound absorption properties.

Over the decades, LFT-D has evolved into a leading-edge production model, slowly moving from simple products to complex, functional products in the automotive sector, and LFT is beginning to replace some traditional processes in many areas outside of automotive manufacturing.

MDC offers automotive lightweighting solutions, contact us today for LFT-D molding solutions.

Contact US

Email: master@zjmdc.com

Tel: +86 576 84616076

Fax: +86 576 84616079

Mobile: +86 13906573507(Mr. Wang)

Address: No.116 mochuang road, Huangyan Xinqian street,Taizhou,Zhejiang,China