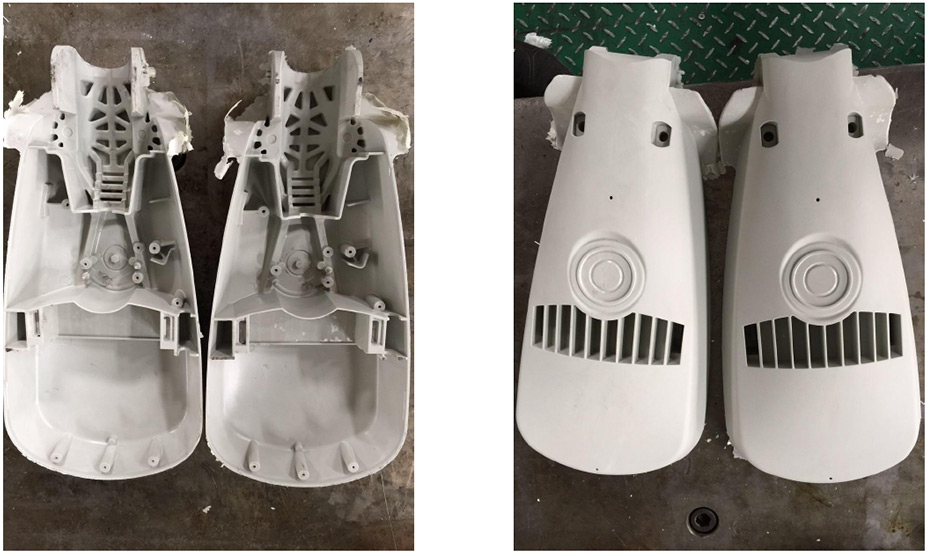

Specialize in Compression molds

Specialize in Compression molds

In recent years, the emergence of new materials and advanced manufacturing processes has accelerated the development of composite materials toward higher performance, greater efficiency, lower cost, and improved sustainability. This trend is driving the application of composites in commercial aircraft to new levels, making them a critical benchmark in evaluating the advancement of next-generation civil aviation programs.

Today, composite usage in major aircraft models continues to climb. The Airbus A350 features composites in 53% of its structural weight, while the Boeing 787 Dreamliner incorporates 50%. China’s domestically developed wide-body aircraft is also expected to achieve a similar level. Aircraft fuselages, wings, and secondary load-bearing components increasingly rely on composites. Over 90% of these parts are produced using autoclave molding processes, with epoxy-based carbon fiber prepregs as the primary material. Airbus plans to raise A350 output to 12 per month by 2028, while Boeing has reached up to 13 B787 units per month in past production cycles.

Beyond autoclave technology, liquid molding processes are advancing rapidly. Europe, the U.S., and Russia have all invested heavily in alternatives such as Resin Transfer Molding (RTM) and Vacuum Assisted Resin Infusion (VARI). These techniques are now the leading non-autoclave processes for resin-based composites and have expanded from secondary to primary load-bearing structures. Their advantages include lower production costs, scalability, and the potential for batch manufacturing of large aerospace components.

Thermoplastic composites have achieved remarkable progress in recent years. Compared to thermoset composites, thermoplastic systems offer greater toughness, better flame resistance, and compatibility with various non-autoclave manufacturing methods. They deliver shorter cycle times, reduced costs, and higher efficiency. Initiatives such as the EU’s Clean Sky and NASA’s HiCAM (High-Rate Composite Aircraft Manufacturing) program highlight thermoplastics as a strategic research priority, making this one of the fastest-growing areas in aerospace composites.

With rising use of composites, the industry faces challenges in recycling and sustainability. Emerging green composite technologies aim to mitigate these impacts through biodegradable polymers and eco-friendly matrix materials. Though currently in the R&D stage, these solutions will play a vital role in achieving long-term sustainability in aerospace manufacturing.

Another area of advancement is the development of high-performance prepregs. Companies like Hexcel (IM10 carbon fiber) and Toray (T1100/3960 prepreg system) have launched materials with superior strength and stiffness. Toray’s TC1130 thermoplastic prepreg also solves the problem of low bonding strength, expanding the potential of thermoplastic composites in critical aerospace structures.

The history of commercial aviation demonstrates that composite technology has continually advanced with each new generation of aircraft. In the future, adoption levels will rise further, particularly in areas such as:

For China’s aviation industry, increasing R&D investment and strategic planning are essential. By fostering innovation in these directions, domestic manufacturers will ensure that future commercial aircraft composites remain competitive on a global scale while meeting both performance and sustainability objectives.

At Zhejiang MDC Mould Co., Ltd. (MDC), we are dedicated to advancing mold and tooling technologies for the aerospace sector. Our expertise covers SMC molds, BMC molds, compression molds, carbon fiber molds, and advanced composite tooling. By leveraging precision engineering, innovation, and sustainability, MDC continues to support the aerospace industry’s transition to a high-performance, cost-effective, and greener future.

Contact US

Email: master@zjmdc.com

Tel: +86 576 84616076

Fax: +86 576 84616079

Mobile: +86 13906573507(Mr. Wang)

Address: No.116 mochuang road, Huangyan Xinqian street,Taizhou,Zhejiang,China