Specialize in Compression molds

Specialize in Compression molds

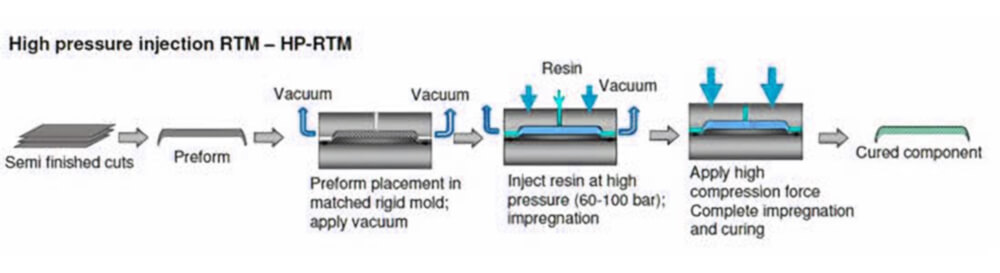

High pressure resin transfer molding (HP-RTM) uses preformed parts, hp-rtm molds, vacuum assisted exhaust, high pressure injection to complete the impregnation and curing process of high performance thermoset composites to achieve low cost, short cycle time (high volume) and high quality production.

Keywords introduced in the above presentation.

High Pressure: High pressure here is relative to the traditional RTM (Resin Transfer Molding) process, HP-RTM increases the injection pressure to 80 bar. the benefit of high pressure injection is that the resin can reach each corner faster, thus increasing the fiber content of the product, improving product performance and making it more suitable for parts with complex shapes.

Pre-laid: here pre-laid fiber reinforcement is fiber material that has been cut and pre-shaped.

Pre-placed insert: the insert is the part placed in the mold before molding, the material has metal and non-metal, so that after molding the product, the insert is wrapped into its own structure and is not removable. The need for pre-positioned inserts is determined by the structural design of the product.

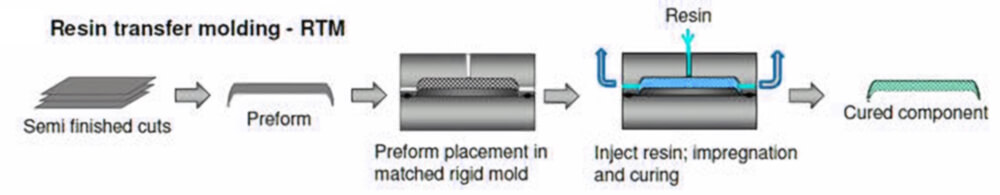

It is a molding process in which resin is hedged and mixed using high pressure and injected into a vacuum-sealed mold pre-lined with fiber reinforcement and pre-molded inserts to obtain composite products through resin flow filling, impregnation, curing and demolding. These processes allow high performance structural components to be obtained by directly combining the reinforcement with the matrix. In-line high-pressure impregnation allows manufacturers to minimize raw material costs. This process is well suited for complex 3D geometries and long fiber reinforcement.

In the standard RTM process, the system components (resin and hardener) are usually mixed at relatively low pressure (<15 bar). In HP-RTM, mixing is managed by reacting the components at high pressures (typically over 50 bar) in a cylindrical mixing chamber. The laminar fluid is quickly transferred into the cavity through the injection nozzle, which is mounted in a hole drilled in the mold without waste.

With standard RTM, production of parts in the mold can take anywhere from 15 minutes to over an hour. In most cases, post-curing is required to achieve final performance. With the HP-RTM optimized resin system, finished parts can be produced in less than 5 minutes.

MDC HP-RTM is used in multiple industries such as automotive manufacturing, aircraft manufacturing, agricultural machinery, rail transportation, wind power, and sporting goods. Contact us immediately for HP-RTM mold projects.

Contact US

Email: master@zjmdc.com

Tel: +86 576 84616076

Fax: +86 576 84616079

Mobile: +86 13906573507(Mr. Wang)

Address: No.116 mochuang road, Huangyan Xinqian street,Taizhou,Zhejiang,China