Specialize in Compression molds

Specialize in Compression molds

Medical compression molding is an advanced manufacturing process that utilizes precisely controlled heat and pressure to shape composite materials within a closed mold cavity. This process ensures excellent dimensional accuracy, surface quality, and mechanical performance, making it particularly suitable for the medical industry, where reliability, safety, and consistency are critical.

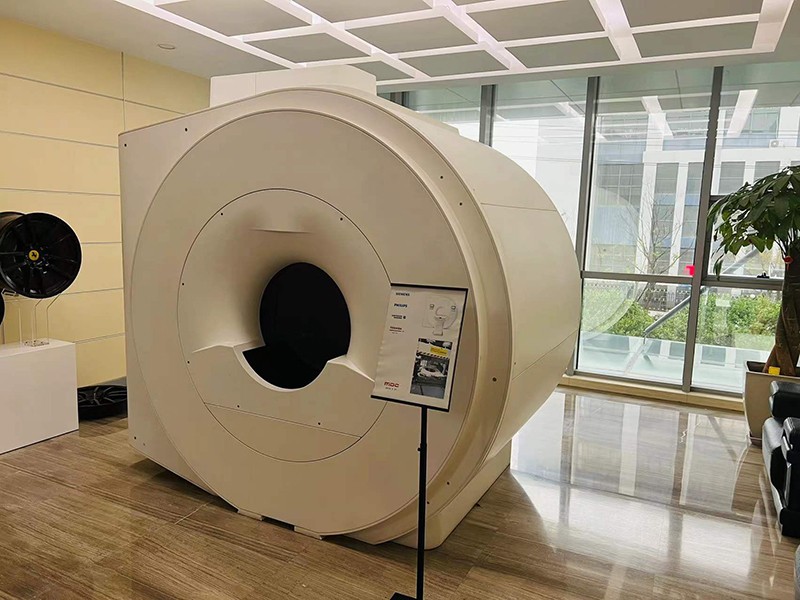

At MDC, medical compression molding is widely applied to the production of large medical equipment housings, complex structural components, and custom-shaped medical parts. These products are commonly used in hospitals, clinics, research institutions, and advanced medical equipment manufacturing facilities worldwide.

The superior quality of MDC’s medical compression molding products is ensured by a dedicated team of professional engineers and quality inspectors. Each production stage is strictly controlled, from raw material selection and formulation to molding process optimization and final product inspection.

By implementing standardized quality management procedures, MDC guarantees:

SMC mould (Sheet Molding Compound mould) is a specialized type of composite mould widely used in medical compression molding. SMC materials offer outstanding advantages, including high strength-to-weight ratio, corrosion resistance, electrical insulation, and design flexibility.

MDC provides a wide range of SMC medical moulds tailored to customer specifications. Leveraging advanced composite molding technology, MDC continuously develops innovative solutions to support the growing demand for lightweight, durable, and aesthetically refined medical components.

In medical compression molding, the selection of mold steel plays a crucial role in performance and service life. MDC offers two primary mold steel options for SMC medical moulds:

Carbon steel is typically used for general medical products that require high strength, rigidity, and cost efficiency. It is suitable for stable indoor environments where corrosion resistance is not a primary concern.

Stainless steel medical moulds are designed for applications that demand high corrosion resistance, cleanliness, and biocompatibility. They are ideal for medical components exposed to frequent cleaning, chemical disinfectants, or strict hygiene standards.

The choice between carbon steel and stainless steel is determined based on the user’s operating environment, regulatory requirements, and expected service conditions.

MDC’s medical compression molding solutions are widely applied in advanced diagnostic and treatment equipment, including:

These components require excellent mechanical stability, smooth surface quality, and precise dimensional control, all of which are achieved through optimized SMC compression molding processes.

With extensive experience in medical compression molds and SMC mould manufacturing, MDC provides reliable, customized, and future-oriented solutions for the medical industry. Our commitment to engineering excellence and continuous innovation ensures that every mold meets the highest standards of performance, durability, and quality.

As medical technology continues to evolve, MDC will continue to expand its composite molding capabilities to support next-generation medical devices and healthcare solutions.

Contact US

Email: master@zjmdc.com

Tel: +86 576 84616076

Fax: +86 576 84616079

Mobile: +86 13906573507(Mr. Wang)

Address: No.116 mochuang road, Huangyan Xinqian street,Taizhou,Zhejiang,China