Specialize in Compression molds

Specialize in Compression molds

A press tool is a mechanical device used in various manufacturing processes to shape or cut material using a die, typically through mechanical or hydraulic means. Press tools are primarily utilized for operations such as stamping, bending, punching, blanking, forming, and deep drawing. These tools are crucial for producing high-precision, repeatable parts in industries ranging from automotive and aerospace to electronics and consumer goods manufacturing.

In this article, we will explore what press tools are, their types, applications, and the key factors that make them essential in modern industrial production. Additionally, we will dive into the design and maintenance considerations that contribute to the tool’s effectiveness and longevity.

A press tool operates by applying force to a workpiece through a die. The die is designed to shape or cut the material in a specific manner based on the operation being performed. The force applied can be mechanical, hydraulic, or pneumatic, depending on the type of press used. This force is typically applied by a press machine, which can be powered either manually or via automated controls for higher volumes of production.

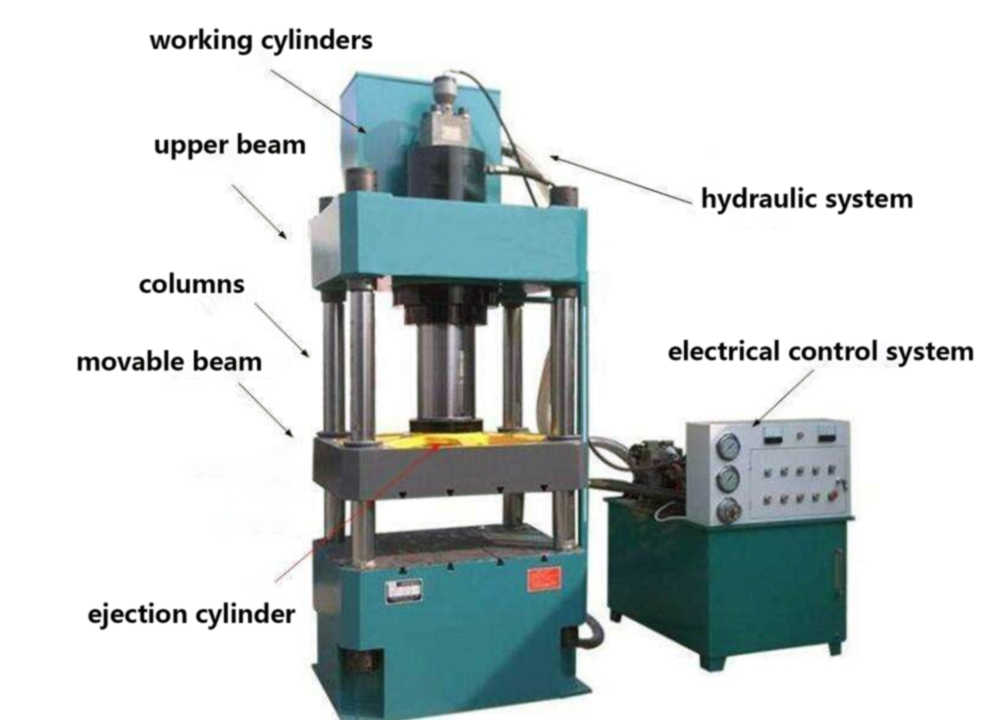

The press tool consists of several components:

Press tools can be classified based on their operation and the specific material processing required. Below are some of the most common types of press tools:

Cutting press tools are designed to cut or shear materials into shapes or parts. This is one of the most common applications of press tools. It includes operations like:

Forming press tools shape materials without removing material, but rather by deforming the material to a desired shape. These tools include:

Blanking involves cutting out a piece from a larger sheet of material to form the initial part. These are essential in producing parts that need to be further processed in other stages of manufacturing.

Progressive press tools are used in continuous stamping processes, where the material is fed through a series of dies in a single pass. Each die performs a different operation, such as punching, bending, or blanking, and the part is progressively shaped until the final form is reached.

Transfer press tools involve the movement of material from one die to another, often used in more complex manufacturing processes where multiple shaping and cutting steps are required.

Press tools play a vital role in numerous industries and sectors, as they enable high-precision, high-volume manufacturing. Below are some of the most common applications:

In the automotive industry, press tools are used to produce body panels, brackets, engine components, and other high-strength parts. These parts often require high precision and durability, making the design and operation of press tools crucial to the success of the manufacturing process.

The aerospace industry also relies heavily on press tools for producing parts that need to meet strict strength, weight, and reliability requirements. Press tools are used to manufacture lightweight but high-strength components, such as airframe panels, wing skins, and brackets.

In the electronics industry, press tools are used to manufacture housings, covers, and brackets for consumer electronics, computers, and communication devices. Precision press tooling ensures that these components meet the intricate requirements for electronic devices.

From appliances to toys, consumer goods manufacturing frequently utilizes press tools to produce parts that require high-volume production and precision, including metal or plastic parts.

The effectiveness of a press tool relies heavily on its design and the material being processed. Several factors must be taken into account when designing a press tool:

In summary, press tools are essential in various manufacturing processes due to their ability to create high-precision, repeatable parts. Whether for cutting, forming, or shaping, the correct press tool can significantly improve productivity, reduce material waste, and ensure the high-quality performance of the parts produced.

For manufacturers looking to invest in press tools, understanding the various types and applications, as well as the factors that affect tool design and performance, is essential to optimizing production and achieving long-term success.

Contact US

Email: master@zjmdc.com

Tel: +86 576 84616076

Fax: +86 576 84616079

Mobile: +86 13906573507(Mr. Wang)

Address: No.116 mochuang road, Huangyan Xinqian street,Taizhou,Zhejiang,China