Specialize in Compression molds

Specialize in Compression molds

As lightweight design, structural integration, and high-volume manufacturing continue to shape modern industries, advanced composite molding technologies have become essential. Among these technologies, thermoforming molds, thermoset molds, and compression molding tooling play a decisive role in determining part quality, production efficiency, and long-term durability.

This article provides a comprehensive overview of thermoforming tooling, thermoset plastic molding, and the compression molding process, helping manufacturers select the most suitable mold solution for composite applications.

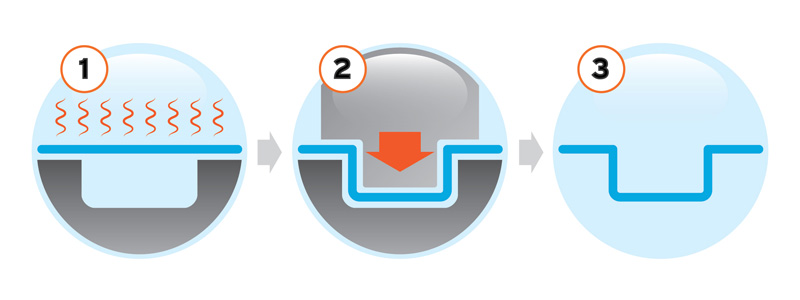

Thermoforming is a manufacturing process in which heated thermoplastic sheets are shaped over or into a mold using vacuum, pressure, or mechanical force. The thermoforming mould defines the final geometry, surface finish, and dimensional accuracy of the part.

Modern thermoforming tooling is commonly manufactured from aluminum or composite materials, offering excellent thermal conductivity and dimensional stability.

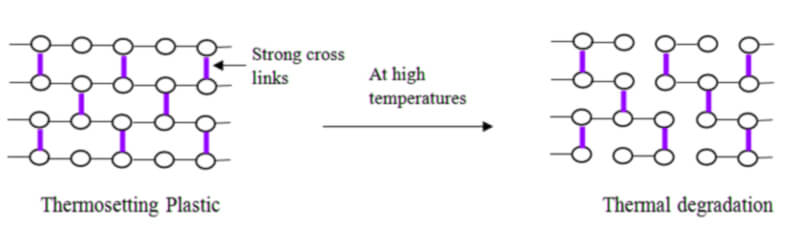

Unlike thermoplastics, thermoset plastics undergo an irreversible chemical curing process. Once cured, the material cannot be remelted or reshaped. A thermoset mold is specifically designed to withstand high pressure, elevated temperature, and repeated curing cycles.

Thermoset molds are typically manufactured from hardened steel or high-strength alloy materials, ensuring long service life and excellent surface finish.

Compression molding is one of the most widely used processes for thermoset composite manufacturing. In this process, a pre-measured charge of thermoset material is placed into a heated mold cavity and compressed under controlled pressure and temperature.

Precision compression molding tooling ensures uniform material flow, minimal voids, and consistent mechanical properties across high-volume production runs.

| Aspect | Thermoforming Mold | Thermoset Compression Mold |

|---|---|---|

| Material Type | Thermoplastic | Thermoset Plastic |

| Recyclability | High | Limited |

| Tooling Cost | Lower | Higher |

| Structural Strength | Moderate | Excellent |

| Typical Applications | Interior panels, packaging | Automotive, electrical, structural components |

Selecting between thermoforming tooling and thermoset compression molding depends on several critical factors:

For high-strength, load-bearing composite components, thermoset molds and compression molding remain the preferred solution. For lightweight, cost-sensitive, and recyclable applications, thermoforming molds offer outstanding advantages.

At Zhejiang MDC Mould Co., Ltd., we specialize in the design and manufacturing of thermoforming molds, thermoset molds, and compression molding tooling for global customers.

Our tooling solutions are widely used in automotive, electrical, energy storage, and industrial composite applications, ensuring high precision, long mold life, and stable mass production performance.

By combining advanced engineering, material expertise, and strict quality control, MDC delivers reliable composite mold solutions that support the future of lightweight manufacturing.

Contact US

Email: master@zjmdc.com

Tel: +86 576 84616076

Fax: +86 576 84616079

Mobile: +86 13906573507(Mr. Wang)

Address: No.116 mochuang road, Huangyan Xinqian street,Taizhou,Zhejiang,China