Specialize in Compression molds

Specialize in Compression molds

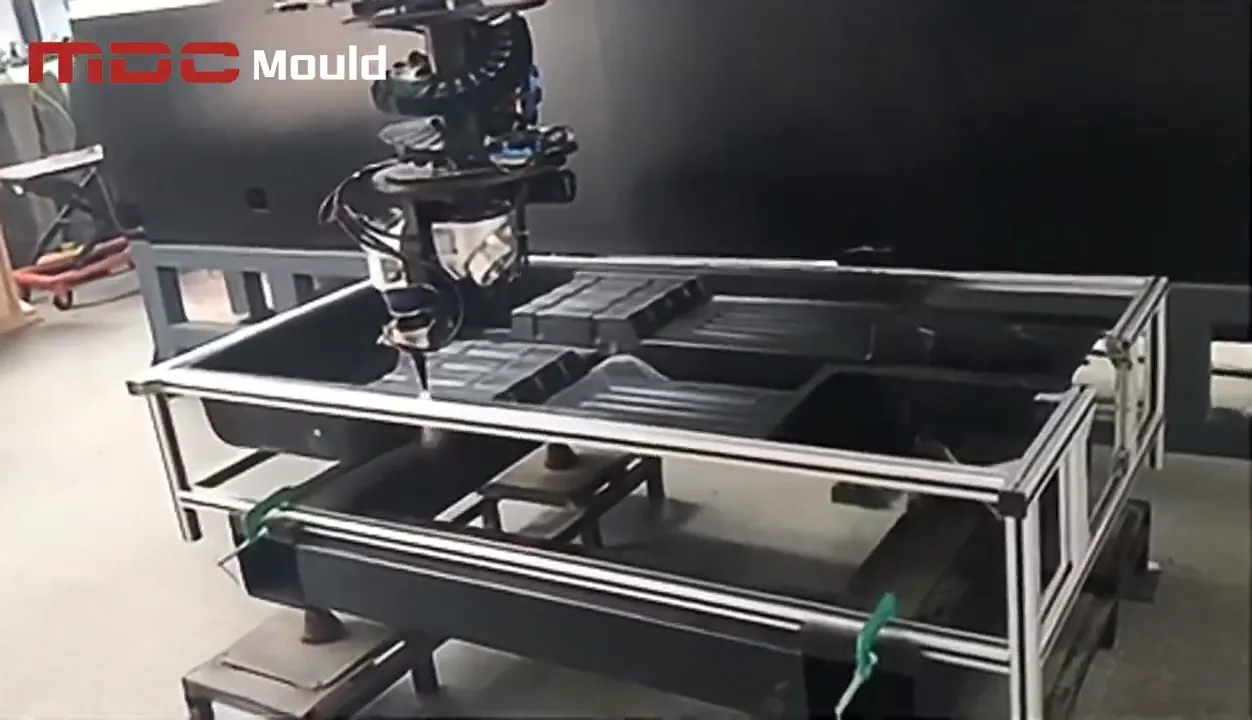

At MDC Mould, our commitment to excellence in composite part processing is reflected in every step of our workflow — including the precision trimming of molded parts. One of the critical stages in composite production is post-molding trimming, and we’ve taken this further by integrating high-precision laser cutting with custom-designed, in-house-built fixtures.

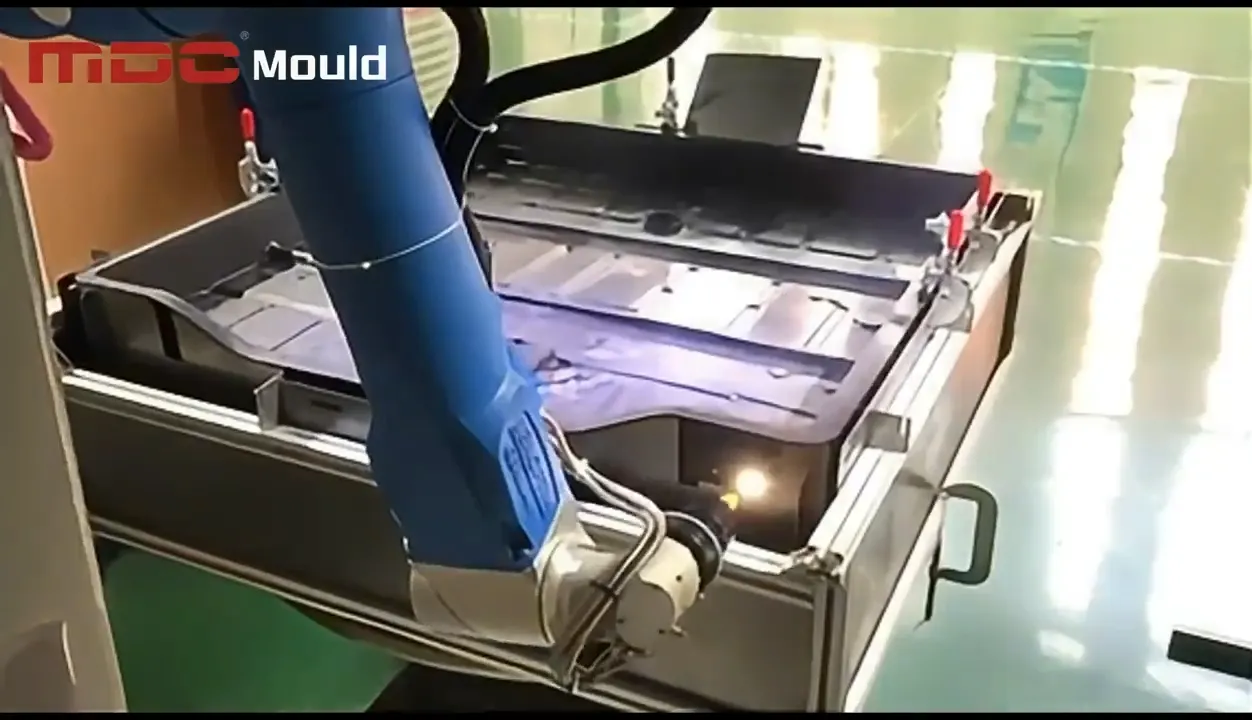

Laser cutting has become a go-to solution for SMC parts and other composite components that require high accuracy, clean edges, and minimal material disruption. Unlike mechanical trimming methods, laser technology allows us to maintain the structural integrity of molded parts while producing highly accurate edges with tight tolerances.

Our in-house engineering team designs and manufactures laser cutting fixtures specifically tailored to each composite part geometry. This offers several key advantages:

Composite materials like Sheet Molding Compound (SMC) require careful handling during finishing processes. Our laser systems are calibrated to prevent heat damage, delamination, or surface distortion. This ensures that the mechanical properties — such as tensile strength and impact resistance — remain unaffected.

With over 20 years of experience in SMC mould and composite mould development, MDC understands the complete process — from molding to trimming. By designing not only the composite moulds but also the cutting fixtures, we ensure vertical integration and control over every aspect of production quality.

Laser cutting, when combined with MDC's proprietary fixtures, results in unmatched efficiency, edge quality, and production repeatability for composite parts. Whether you're producing automotive panels or industrial housings, our integrated tooling and laser cutting approach ensures your parts are trimmed to perfection.

Interested in precision cutting solutions for your composite products? Contact MDC Mould to explore how we can support your production needs.

Contact US

Email: master@zjmdc.com

Tel: +86 576 84616076

Fax: +86 576 84616079

Mobile: +86 13906573507(Mr. Wang)

Address: No.116 mochuang road, Huangyan Xinqian street,Taizhou,Zhejiang,China