Specialize in Compression molds

Specialize in Compression molds

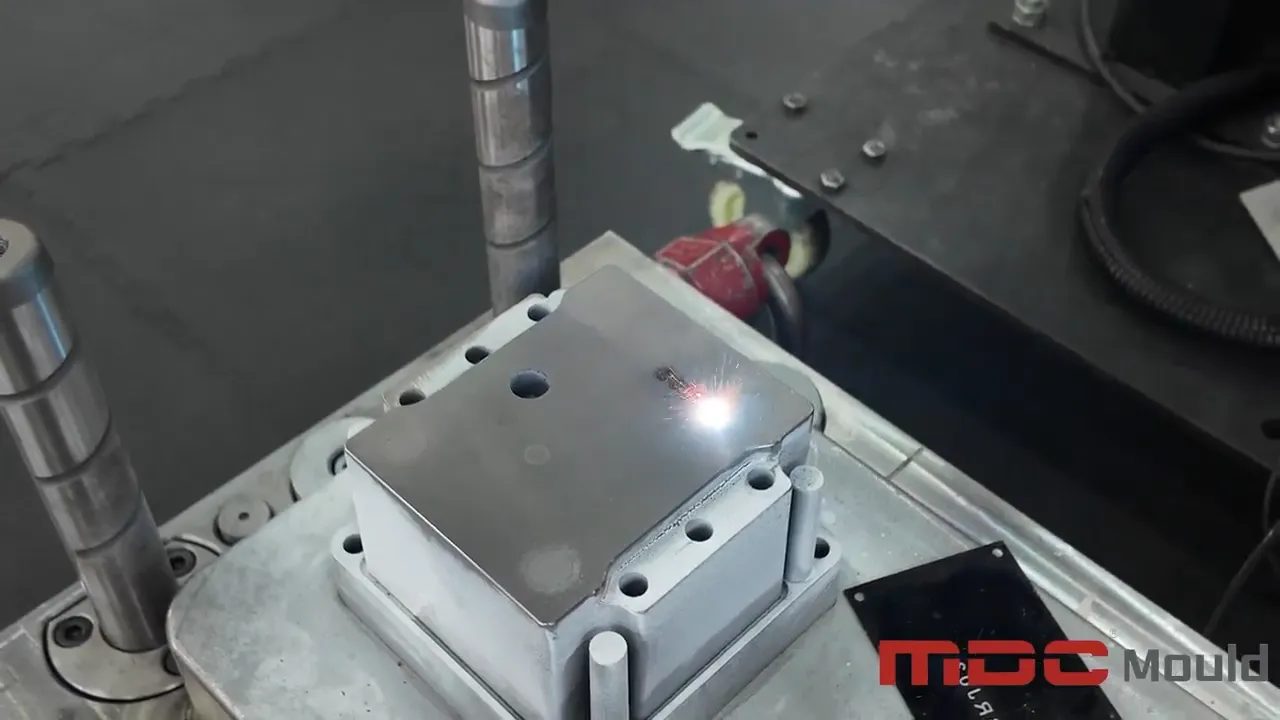

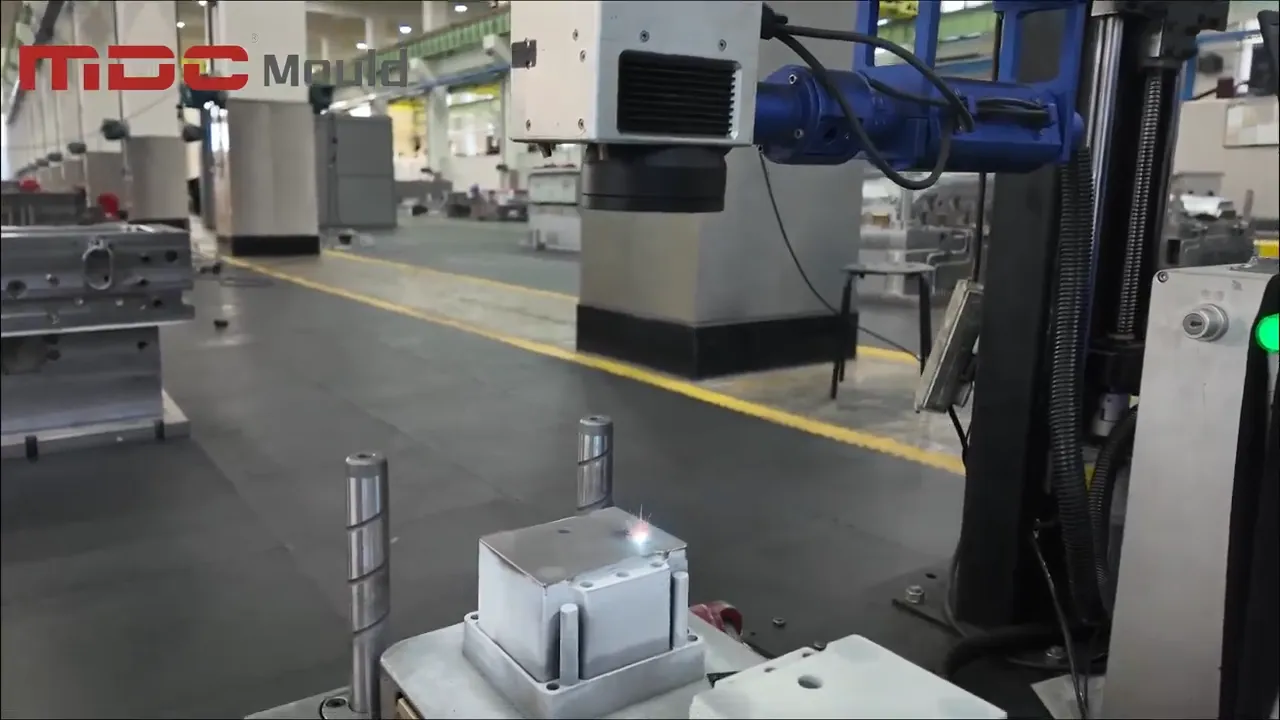

In the field of modern mold manufacturing, precision, traceability, and efficiency are not just requirements—they are essential for delivering high-performance tooling solutions. One of the key technologies enabling this level of excellence is laser marking. At MDC Mould, we integrate laser marking throughout our mold production process to ensure that every component, no matter how small, is clearly identified and easy to service.

Laser marking is a non-contact, high-precision process that uses a focused laser beam to etch permanent identification marks on the surface of a material. In mold manufacturing, this technique allows critical components—such as ejector pins, wear plates, guide pillars, and inserts—to be engraved with unique part numbers, orientation marks, or material specifications.

These marks are resistant to wear, do not damage the material’s surface integrity, and can be applied to metals, hardened steels, and various composite tool materials. This level of precision ensures long-lasting readability and zero compromise on tooling performance.

At MDC, we apply laser marking across a wide variety of mold types, including:

Whether the tooling is intended for high-volume production or precision prototyping, laser marking plays a key role in maintaining mold integrity over time.

At MDC Mould, we believe that innovation lies in the details. Every marked component reflects our commitment to superior engineering and uncompromising quality. We invest in advanced laser engraving equipment and implement stringent quality checks to ensure each mark is precise, permanent, and aligned with our client’s requirements.

Laser marking also reinforces our ISO-compliant quality management system, allowing us to deliver molds that are not only high-performing but also easy to manage and maintain across their service life.

With over two decades of experience in the design and manufacturing of high-performance molds, MDC Mould continues to set benchmarks in precision tooling. Our laser-marking process is just one example of how we integrate smart technologies to add value at every stage—from mold design and machining to testing and final delivery.

If you are looking for a partner capable of delivering laser-marked compression molds, composite tooling, or high-volume production molds with exceptional traceability and quality, contact our engineering team today.

Contact US

Email: master@zjmdc.com

Tel: +86 576 84616076

Fax: +86 576 84616079

Mobile: +86 13906573507(Mr. Wang)

Address: No.116 mochuang road, Huangyan Xinqian street,Taizhou,Zhejiang,China