Specialize in Compression molds

Specialize in Compression molds

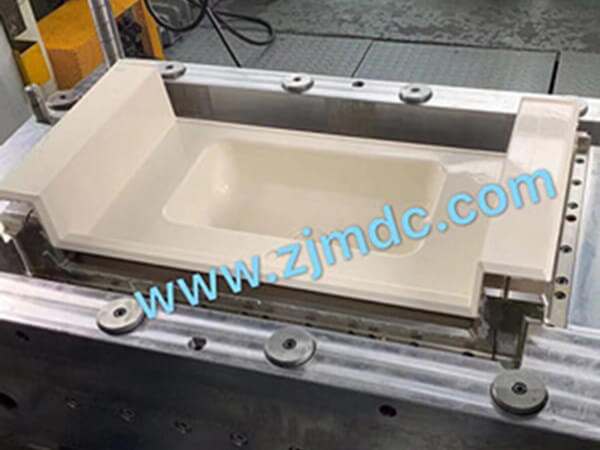

In the sanitary ware manufacturing industry, surface finish is not just about appearance — it's an integral part of performance and precision engineering. At MDC Mould, our ultra mirror polishing technique on sanitary moulds sets a new benchmark in quality and durability.

Mirror polishing offers more than just a shiny appearance. It plays a vital role in the entire production cycle of SMC bathroom components, ensuring a smooth demolding process, minimizing surface flaws, and improving the aesthetic and structural quality of the final product.

When you demand precision tooling and unmatched finish in your sanitary applications, the mirror polishing process is essential. Here are the core benefits:

Delivering an ultra-clear, mirror-like finish on every sanitary mould requires a tightly controlled process and experienced hands. Here's how MDC ensures industry-leading polishing results:

Our polishing process begins with a rigorous inspection and treatment of the cavity base. Whether finished via precision CNC or EDM, our technicians ensure the surface is flat, defect-free, and ready for refinement. This foundational step is critical for avoiding imperfections later in the polishing sequence.

The polishing sequence is conducted by skilled craftsmen using a step-by-step progression of abrasives — from coarse grit to ultra-fine diamond pastes. This multi-stage method includes:

Each stage eliminates the scratches from the previous step. The end result is a glass-smooth tool surface with reflectivity approaching 100% under optical inspection. We often say — you can literally see your reflection in our moulds.

Overheating can compromise the steel’s molecular structure. At MDC, we strictly control polishing pressure, tool speed, and ambient temperature to avoid microcracks, temper loss, or distortion. This ensures the tooling integrity of each SMC mould remains intact during polishing.

We implement ultra mirror polishing on various mould types used in the sanitary and composite industries, including:

Whether for compression moulding or other thermoset composite processes, mirror polishing helps maximize product yield and finish quality.

At MDC Mould, our quality assurance team uses advanced instruments such as surface roughness testers, optical microscopes, and gloss meters to verify every mould. We consistently achieve roughness values of Ra ≤ 0.01 μm — a true reflection of our polishing mastery.

Ultra mirror polishing is more than a finishing touch — it’s a critical step in ensuring the **performance, reliability, and durability** of every **sanitary mould** we produce. When combined with our precision engineering and expert process control, the result is tooling that delivers maximum value, longevity, and visual brilliance.

If you're looking for a reliable partner in compression moulds, SMC moulds, or high-performance mirror polished tooling, MDC Mould is ready to deliver.

Contact US

Email: master@zjmdc.com

Tel: +86 576 84616076

Fax: +86 576 84616079

Mobile: +86 13906573507(Mr. Wang)

Address: No.116 mochuang road, Huangyan Xinqian street,Taizhou,Zhejiang,China