Specialize in Compression molds

Specialize in Compression molds

Most compression molds are hot compression molds, which is due to the nature of most composites. The temperature of the mold for hot compression molding ranges from 300-400 degrees Fahrenheit, but can reach up to 1200 degrees Fahrenheit

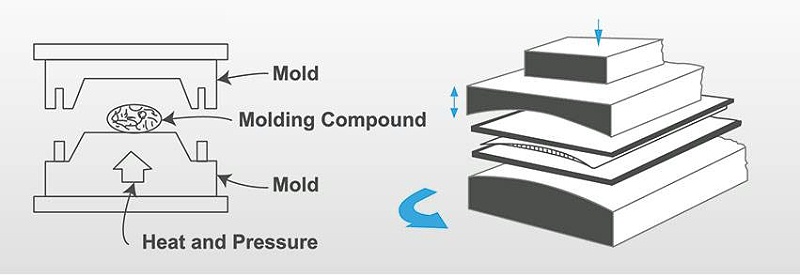

What is hot compression moulding? Hot compression moulding is a technology that can heat and solidify the material on the mould into the desired product at an appropriate temperature and pressure. First, the composite material is placed in an open heating mold. Close the mold and apply pressure to force the material into contact with all mold areas while maintaining the heat and pressure until the material solidifies.

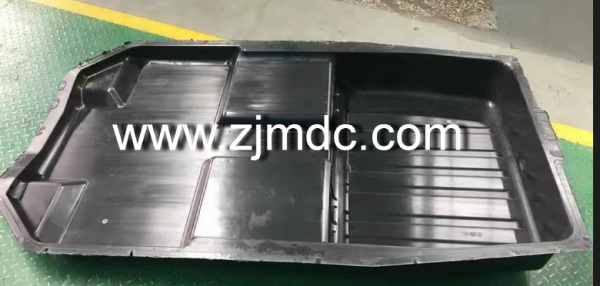

Heat compression molding is a versatile manufacturing process used by both small and large production companies to make a wide variety of parts, from large aircraft parts to small baby bottle nozzles. MDC mould uses it primarily for mass production of structural and non-structural parts for automotive series and high volume (often small) aerospace parts. Recently, MDC has developed several sets of electric vehicle parts, like SMC battery house, GMT hood, undertray, carbon fiber door panels, etc., all formed by hot compression.

The hot compression mould has the advantages of simple structure, low manufacturing cost, low moulding pressure and high precision. In mould design, considering a large number of mounting holes around the battery box, direct forming can greatly reduce the subsequent labor costs. In mould milling, MDC has High speed CNC milling machines and Five-axis milling at workshop, to ensure the precision and accuracy of the mould. In mould tests, MDC has big pressure machines ranging from 500 till 4000T.

The hot compression moulding process has broad application prospects, but when the hot compression technology is used to make moulds, there are still some problems, for example, the uneven cooling during the demolding process will cause demolding defects. In the hot compression moulding process, the temperature of the mould needs to be lowered before demolding to ensure that the polymer filling the cavity is completely cured.

In addition, the cooling phase of the mould will extend its moulding time, so mould manufacturers can improve the efficiency and quality of hot compression moulding by accelerating the thermal cycle rate of the mould. Mould temperature will affect the part quality and its productivity, so it is necessary to strictly control the temperature during moulding. The heating method mainly adopts electric heating, steam and oil.

using electric heaters to heat the mold, which has the advantages of fast heating speed, uniform temperature distribution and easy control. However, there are also some disadvantages: high power consumption, high cost of use and low efficiency; in addition, any leak of electricity may cause personal injury or damage to equipment. For small-sized molds, it is often used for oil heating.

Steam heating is a commonly used method of hot compression molding. However, when using steam for molding, it is necessary to pay attention to the problem of condensation water in the runner system and the insulation layer of the mold. It is necessary to periodically check whether the insulation layer is aging and whether there is leakage in order to ensure safe production.

Oil heating directly heats the oil through the mould temperature controller, to setting the appointed temperature after several hours. when changing the mould, the mould temperature controller will be like an oil storage tank. In the meantime, the self-closing joints are used for the butt connection of the mould oil passage and the oil temperature controller. Which is easy to connect and disconnect, furthermore it can be completed in seconds. The oil heating system is widely used in composite material and RTM moulding.

Choose a method of heating according to the existing conditions of each company and mould size. Hot compression moulding is a new type of composite material moulding method, good product quality is guaranteed by a stable compression mould. Therefore, reasonable design, high-precision manufacturing and process improvement of hot compression moulds have become the key to improving the quality of hot compression products.

Hot compression molding and wet compression molding are two different types of compression molding processes. The main difference between them is the temperature at which the material is formed.

Hot compression molding occurs at temperatures in excess of 300 degrees Fahrenheit (150 degrees Celsius). In this type of process, the plastic material is first heated and then compressed into the mold. After the plastic has cooled and cured, it is removed from the mold and finished. This method is commonly used to make large objects such as car bumpers, boat hulls and other parts that require high strength or durability.

The temperature of wet compression molding is lower than that of hot compression molding, usually below 200 degrees Fahrenheit (90 degrees Celsius). However, like hot press molding, wet press molding requires heating of the plastic sheet before it is pressed into shape. Wet press molds are often used to make smaller items, such as toys or kitchen items such as spatulas, bowls or cups because they can be made quickly and inexpensively compared to other types of molds, such as injection molds or blow molds.

With the development of the composites industry, the technical requirements and innovative development for compression mould are getting higher and higher. MDC, as a professional compression mould manufacturer, Not only in terms of equipment but also in terms of technological innovation, needs continuously progress to suit the market. Contact with compression mould maker-MDC, will provide you with the solutions.

Contact US

Email: master@zjmdc.com

Tel: +86 576 84616076

Fax: +86 576 84616079

Mobile: +86 13906573507(Mr. Wang)

Address: No.116 mochuang road, Huangyan Xinqian street,Taizhou,Zhejiang,China