Specialize in Compression molds

Specialize in Compression molds

Description: Injection molding and compression molding are the most common processes for manufacturing plastic parts. Let's take a look at the differences and similarities between the two processes.

Plastic remains one of the most popular materials used to manufacture a large number of consumer products. Potential uses for this material continue to expand into different industries. Likewise, we cannot ignore the increasing number of such material technologies. Molding is one of the most common fabrication processes involving materials such as plastic, rubber, and similar polymers. However, it must be noted that not all molding processes are the same.

Both compression molding and injection molding are efficient, economical, and versatile methods of manufacturing high-quality components. While they have similarities, both types of molding offer unique benefits. Therefore, we need to compare compression molding and injection molding to determine which method is more suitable. In most cases, the specification of the application usually determines which type of process is best for the product. So, what is the difference between compression molding and injection molding? Let's start the discussion!

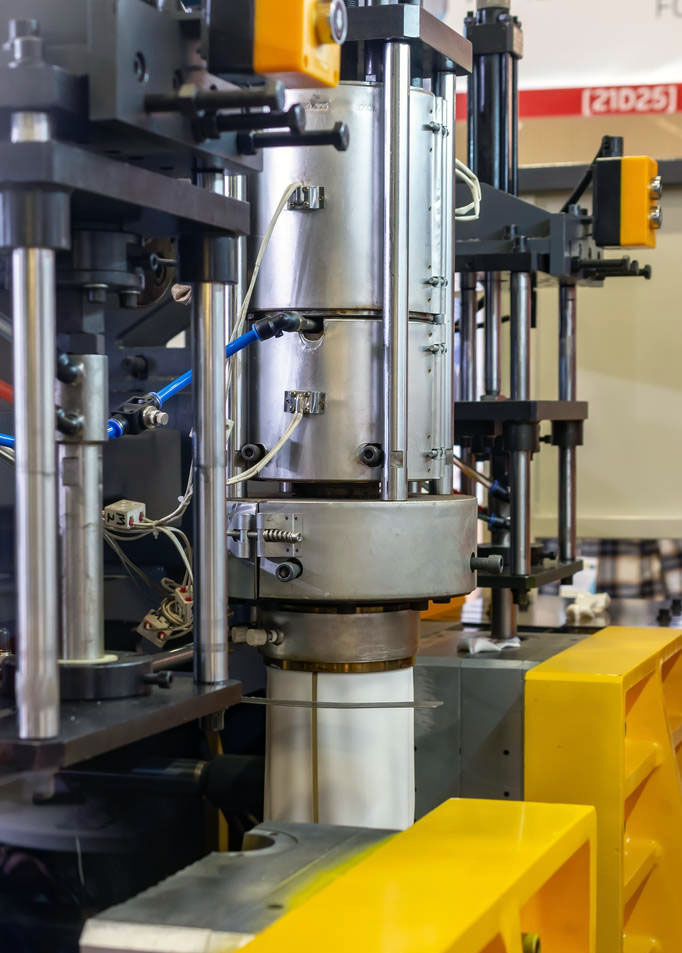

Injection molding is a process that involves the use of "injection molding" techniques. The term "injection molding" is due to the process that typically involves injecting raw material into a mold cavity. During the injection molding process, the material is fed into a hopper by a screw, followed by a heating process, and finally injected into the mold cavity. The heated material cools and solidifies in the shape of the mold cavity.

Injection molding is ideal for manufacturing complex parts and high volume production. If the component is to be manufactured using injection molding, the manufacturer is limited to designing and creating a steel mold based on the user's product. After the mold is created, the manufacturer injects the molten plastic formula into the mold, where it cools and solidifies into the shape of the mold cavity.

This approach offers many benefits in terms of production. It is the best choice for creating complex parts but is also suitable for large production runs. If you want consistency, accuracy, and versatility in your work, then injection molding is the way to go.

Some of the advantages of injection molding compared to compression molding include:

Here are some disadvantages of injection molding that you need to be aware of:

Due to the versatility of injection molding, it is suitable for a wide range of applications. It helps create everything from complex assemblies to appliances. In addition, injection molding is now very common in the production of auto parts. Some of its applications include:

Generally, compression molding is defined by the application of heat and pressure. While this is similar to injection molding, the process is very different. During compression molding, manufacturers place raw material in a mold cavity where healing occurs. The operator then inserts a plug into the top of the cavity to seal it, and then the plug also helps to apply further pressure to the cavity.

The combined action of heat and pressure cure the raw material in the mold cavity, resulting in a new component. Therefore, unlike injection molding, compression molding does not fill the cavity with molten plastic material. Instead, it involves placing material into an already heated cavity.

Some of the advantages of compression molding include:

It will help if you can keep in mind the following disadvantages of compression molding:

Compression molding can provide a strong and durable product. So, many industries tend to adopt this technology in their applications. Some typical applications for compression molding include:

Although compression molding and injection molding are different technologies, they also share certain similarities. Both processes involve the molding of plastic materials. So, we expect some common characteristics. Let's explore these common characteristics together!

Both injection molding and compression molding processes can create custom-colored plastic resins that are used to make custom parts. Certain applications require parts to have a specific color for aesthetic purposes and to bring the product to life. These processes allow the use of pre-mixed colors for manufacturing purposes.

They also support masterbatch colors that involve mixing for coloring plastics. In this case, you can get up to 2% of the color (by volume). Another popular way of involving injection molding and compression molding is solvent coloring. This process involves mixing the tinted oil and solvent before spraying on the unpigmented granules. The coating here is done before injection molding.

Finally, they also support dry paint mixing. Here, the operator will mix the plastic resin with the dry pigment powder in the hopper. In some cases, it may be necessary to dry the particles before adding resin. So, injection molding and compression molding methods allow you to use the color you want, regardless of your application.

Both injection molding and compression molding techniques are very common because the process of both processes is relatively simple, and the operator only needs basic skills to complete these processes. Also, both processes support automation. Automated machines and robotics perform most of the production process. This automation ensures a reduction in overall injection molding costs. Labor costs are significantly reduced because only one operator is required to monitor the operation of the machine.

Both processes can be accomplished with less infrastructure, and they generally do not require any additional molding features other than the cavity feature itself. Forming tools can come from a variety of materials, including aluminum and low-cost steel, which is often a reduction in tooling costs while using high-quality materials.

Additionally, molds tend to last longer in both processes, so they can be reused for longer cycle times and produce multiple parts in the same cycle. Combined with reduced tooling and labor costs, injection molding and compression molding are both cost-effective. At the end of production, components are usually affordable, depending on their complexity.

When comparing compression molding and injection molding, there are several important points to consider. It is crucial to understand which of the two methods is the most effective. Also, your application will determine the best method to choose. While above we examined the similar characteristics of both processes, we should also learn more about the difference between compression procedures and injection molding. Next, let's start looking for answers!

The first action point in every manufacturing process is deciding on the materials used for production. Likewise, material selection is a crucial consideration when deciding between compression molding or injection molding. While both processes support a wide variety of plastics, they both have some peculiarities.

| The following materials are generally the best choices for compression molding | Material options for injection molding include |

| Diallyl Phthalate (DAP) | Polyethylene |

| Diallyl Phthalate (DAP) | Polystyrene |

| Thermosetting polyester | Nylon |

| Epoxy resin | Polypropylene |

| Sheet Molding Compound (SMC) | Acrylonitrile Butadiene Styrene (ABS) |

| Vinyl ester | Polycarbonate |

| Phenolic resin | |

|

Silicone |

The process of compression molding appears to be simple as there are relatively few components involved, namely the raw polymer, the plug, and the heated mold. Here is a step-by-step process of how compression molding is done:

On the other hand, injection molding requires a feed hopper, heater, injection unit, clamping unit, hydraulic cylinder, etc. Here's how it works:

Injection molding is often ideal for small batch production. When your application does not depend on multiple prototypes of the same type,

Preferably injection molding. For example, one of the advantages of injection molding compared to compression molding is that it can make your options more practical. This is a low-cost option that can help you identify required changes to your product before total production runs efficiently.

Meanwhile, compression molding is best suited for mass production. Suppose you want to develop multiple prototypes simultaneously within a deadline, in which case you should choose compression molding. It enables you to perform the required QA assurance in a short period of time.

Another advantage of injection molding compared to compression molding is that no post-processing is required due to the high dimensional accuracy. Manufacturers often build molds from durable steel, which gives them high strength, which also means they are less prone to defects that could affect the final shape of the mold.

Also, the operator can easily adjust the heat and pressure levels in injection molding. As a result, it becomes easier to manufacture prototypes with more consistent shapes that require less fine-tuning.

As mentioned earlier, injection molding can produce models of more complex designs than compression molding. So you can easily try out different design ideas with injection molding. Also, you can test your ideas to see how they perform in real life. Compression molding, on the other hand, is more suitable for simple designs and less complex assemblies.

Although compression molding is best for high-volume production, this process has significantly longer lead times than injection molding. The injection molding process is shorter and more reliable for customers who need faster prototype testing. So you don't need to wait before evaluating the productivity of your product. The shorter lead times of injection molding compared to compression molding help manufacturers focus on other important aspects of their operations.

Injection-molded products are more complex, these products often have different wall thicknesses, and they can also be a combination of various shapes. In contrast, compression molding can make a simple block product, and the raw material is simply cut into a shape similar to the final compressed product.

The long discussion about compression molding vs. injection molding continues, and this is the process necessary to find the most efficient way. You probably already got your answer from our comparison above. But in general, compression molding has advantages over injection molding. By using compression molding, you can get molds that will last longer, although the time may be a bit longer, the wait is bearable.

Your choice between compression molding and injection molding often depends on your specific application, and hopefully, our comparison of compression molding vs. injection molding will help you make an informed decision!

When comparing injection molding and compression molding, it is critical to consider the cost. Injection molding tends to be less expensive than compression molding but has a shorter lifespan. But, both methods are generally cost-effective.

In most cases, compression molding is suitable for high-volume production. Also, molds are generally durable and can last a long time. So, if you need to produce a lot of prototypes at once, compression molding would be a great option.

The production process will never be efficient without the best people. MDC provides the best engineers and processes to help you get the best end product. We provide top-notch custom compression molding services at competitive prices.

We are an ISO 9001 certified industry and have extensive experience in producing high-quality compressed parts. Our benefits include free automatic DfM feedback, full-size, and inspection reports. Get an instant quote now and let's get to work.

As a composite expert, MDC can find the best solution for your design and the cost that fits your request. MDC will always provide guidance to ensure that the best cost and quality requirements for you, whether in the compression moulding process or in the mix of raw materials.

Contact US

Email: master@zjmdc.com

Tel: +86 576 84616076

Fax: +86 576 84616079

Mobile: +86 13906573507(Mr. Wang)

Address: No.116 mochuang road, Huangyan Xinqian street,Taizhou,Zhejiang,China