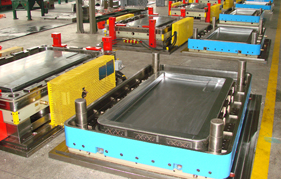

Specialize in Compression molds

Specialize in Compression molds

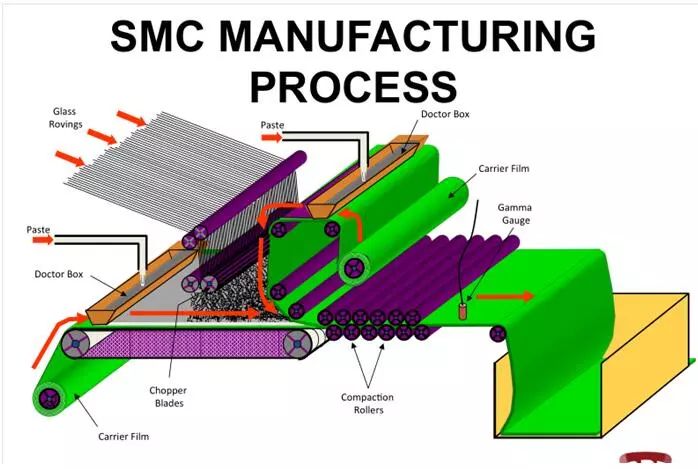

SMC mold is a tool that is matched with plastic molding machines in the plastic processing industry to give plastic products a complete configuration and precise size. Due to the variety of plastic varieties and processing methods, and the complex and simple structures of plastic molding machines and plastic products, the types and structures of plastic molds are also diverse.

The SMC molding process is an advanced composite material molding method, and the mold is the basis of the SMC process. Good product quality is guaranteed by reliable molds.Therefore, in the design of the SMC molding process, the design of the mold is particularly important.

In the design process of SMC molding tools, the cavity of the mold should be designed according to the specific size of the product. In addition, the appropriate material should be selected according to the surface quality requirements of the product and the size of the demand. In order to ensure the quality of the product and the feasibility of the process, the shearing edge and ejection system of the mold should be reasonably designed.

In order to make the product easy to demould, to ensure product accuracy, strength and ease of mold processing, the selection of the parting surface should consider the following principles:

①In order to make the product easy to push out and simplify the ejection mechanism, the position of the parting surface should be such that the product remains in the lower mold as much as possible after the mold is opened;

②Minimize the damage of the flash to the appearance of the product, and at the same time, it should be easy to remove the residual flash;

③It is convenient for mold manufacturing and mold parts processing;

④For products with high requirements on radial dimensional accuracy, the influence of flash thickness on product accuracy should be considered, and the vertical parting surface is used to ensure product radial accuracy;

⑤Ensure the strength of the product and avoid sharp corners and thin walls.

The design of the parting surface is very important. The parting design of the product should be carried out in the early stage of mold design, and the parting design drawings should be drawn to ensure that the product can be demolded smoothly and is easy to produce.

There are three main aspects of SMC mold processing accuracy: dimensional tolerance, geometric tolerance and surface roughness. The processing accuracy requirements we usually ask mold manufacturers are mainly dimensional tolerances and surface roughness. Dimensional tolerances are roughly divided into: external dimensions and cavity dimensions. The two types have relatively loose requirements on the dimensions of the mold, and the actual processing size and the theoretical size error of the mold drawing are not more than ±1.5mm. The dimensional accuracy requirements of the face cavity must be strictly controlled according to the drawings, generally not exceeding 0~0.1mm. We can propose the corresponding mold surface machining accuracy according to the actual product surface requirements.

As the SMC mold shrinks after cooling, the product tightly wraps the mold core and the raised parts in the cavity. In order to facilitate the smooth removal of the product and prevent the product from being bumped or scratched during demolding, when designing the SMC mold, the inner and outer surfaces of the SMC mold should have sufficient demoulding slope along the demolding direction.

MDC Mould is a company specializing in the development and research of SMC/BMC/GMT/LFT moulds and has a good reputation. Adhering to the concept of professionalism and integrity, MDC has established long-term and mutually beneficial partnership with customers. Through mature technology and thoughtful service, MDC has become a suitable and pleasant choice for customers to develop molding and composite molds for their projects.

Contact US

Email: master@zjmdc.com

Tel: +86 576 84616076

Fax: +86 576 84616079

Mobile: +86 13906573507(Mr. Wang)

Address: No.116 mochuang road, Huangyan Xinqian street,Taizhou,Zhejiang,China