Specialize in Compression molds

Specialize in Compression molds

As the global electrical industry continues to advance toward higher power density, improved safety, and long-term reliability, the demand for precision electrical connector components has increased significantly. At the core of these components lies a critical manufacturing element — the electrical connector mould.

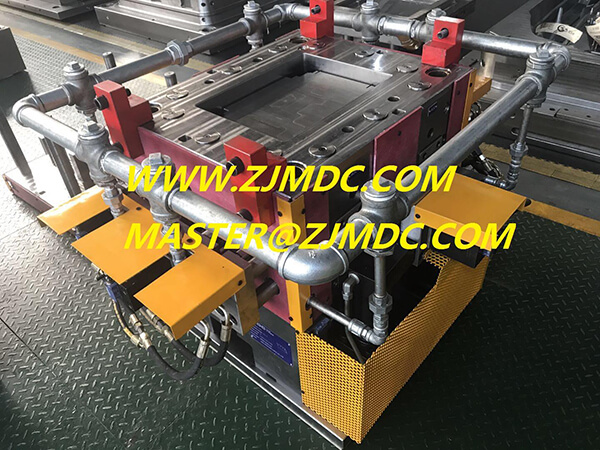

As an important supplier to the electrical industry, MDC has provided a wide range of SMC electrical connector moulds and thermosetting compression mould solutions to customers worldwide. MDC’s extensive experience in SMC mould manufacturing is the foundation of its success in producing high-precision electrical connector tooling.

Electrical connectors play a vital role in power transmission, signal control, and electrical safety. They are widely used in:

These applications require connectors capable of withstanding high temperatures, high voltage, mechanical stress, and long service cycles. As a result, both material selection and mould precision are critical to overall product performance.

Thermosetting moulding is a key manufacturing process used in the production of electrical connectors. Unlike thermoplastic materials, thermosetting materials undergo irreversible cross-linking during curing, providing superior thermal and electrical properties.

Thermosetting materials commonly used in electrical connectors include:

These materials offer:

Due to these properties, thermosetting moulding is indispensable in safety-critical areas of the electronics and electrical industry.

MDC Mould has accumulated rich manufacturing and processing experience in SMC electrical connector moulds. This expertise enables MDC to deliver tooling solutions that ensure stable mass production, consistent quality, and long mould service life.

In addition to SMC, MDC applies a variety of electrical connector materials in actual production, including:

By deeply understanding material flow behavior, curing characteristics, and thermal requirements, MDC optimizes mould structure and processing parameters for each application.

High-quality electrical connectors begin with precision mould engineering. MDC integrates advanced design concepts with high-accuracy manufacturing to ensure each electrical mould meets strict industry requirements.

Through precision CNC machining, strict inspection processes, and experienced assembly, MDC electrical connector moulds deliver reliable and repeatable production performance.

Compared with conventional tooling solutions, MDC’s SMC electrical connector moulds provide:

MDC electrical connector moulds are widely used for manufacturing:

MDC supports both standardized and customized connector mould solutions to meet diverse global market requirements.

With the increasing demand for safety, precision, and durability in electrical systems, SMC electrical connector moulds play a critical role in modern manufacturing.

Through advanced thermosetting moulding technology, deep material expertise, and precision engineering, MDC Mould continues to provide reliable electrical mould solutions for the global electrical industry.

For manufacturers seeking long-term stability and high-quality mass production, MDC’s electrical connector moulds represent a proven and future-ready solution.

Contact US

Email: master@zjmdc.com

Tel: +86 576 84616076

Fax: +86 576 84616079

Mobile: +86 13906573507(Mr. Wang)

Address: No.116 mochuang road, Huangyan Xinqian street,Taizhou,Zhejiang,China