Specialize in Compression molds

Specialize in Compression molds

Plastics come in different sizes, types, colors and different material properties. The wide variety of plastics makes it a key material for manufacturers interested in producing prototypes and end-use parts. Thermoforming is a manufacturing process that offers manufacturers a versatile solution for processing plastic sheets. In this comprehensive guide to thermoforming, you can learn about various thermoforming processes, materials, equipment, and its advantages, disadvantages, and applications.

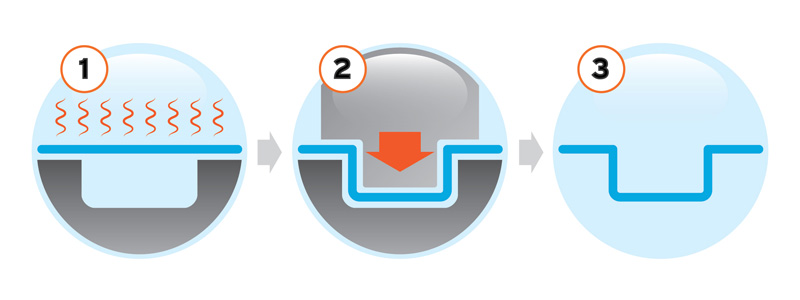

Thermoforming is a plastic molding technique that works with a variety of polymers to produce a variety of highly usable products. Initially the thermoplastic sheet is clamped into a fixture and heated using convection or radiant heat until it softens. The sheet is then held horizontally on the mold and pressed into the mold using vacuum pressure, air pressure, or mechanical force. The softened sheet fits tightly into the mold cavity until it cools and solidifies into the desired shape. The final product is eventually trimmed to increase its usability. For some plastics, you can regrind the excess material and mix it with the unused plastic,

This technology is the most basic thermoforming technology. In this method, the plastic sheet is pulled towards the mold cavity with the help of vacuum and heat. The vacuum pressure (typically 14 psi) should be uniform throughout the mold. The vacuum process is known for its cost-effectiveness and speed of the manufacturing process. Used to produce items where precision and accuracy are not critical, such as household items and packaging

The pressure forming process also involves the heating of the plastic sheet and the use of a vacuum to draw air away to force the sheet against the mold. But there is an extra step. After the air is removed, a pressurized tool applies pressure (usually 50 psi) to ensure that the molded plastic better retains its final shape. This pressure allows for more detail (such as textured surfaces, undercuts and sharp corners) and is suitable for products with complex designs.

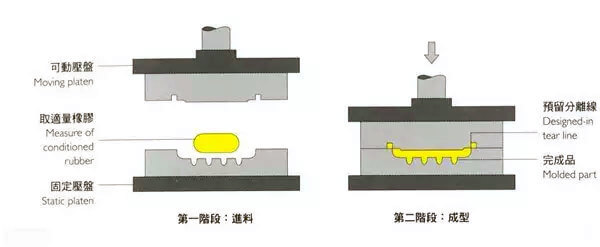

This process involves the use of direct mechanical force to form preheated plastic sheets. Using a combination of positive and negative molds, the thermoplastic sheet is mechanically pushed into or around the mold cavity. The core plug pushes the sheet into the cavity and forces it into the desired shape. This prints the surface pattern on the plastic sheet. It provides better dimensional and part thickness control than vacuum and pressure forming. However, this is expensive because of the operation and maintenance of both mold halves.

A process in which two plastic sheets are heated, formed, and joined together to produce an item at the same time. The double-panel forming process is most suitable for making hollow items or items with double walls, such as ducts, pipes, and tanks.

In drape molding, a heated plastic sheet is draped from a mandrel designed with a specific pattern. The drape forming process is one of the most economical thermoforming techniques.

The match-die forming process involves the use of male and female dies to form heated plastic sheets and is suitable for making items that require greater precision.

Thermoforming enables manufacturers to produce high-volume products at an affordable cost compared to other traditional manufacturing processes. And it can lead to impressive final designs and high customer satisfaction.

While thermoforming has several advantages, it is not without its disadvantages. Plastic sheets can be damaged and waste about 20% of the raw material. Also, it is difficult to create sharp bends and corners. Some of the major disadvantages of thermoforming are listed below.

Each thermoforming process requires specialized equipment, for example, vacuum forming, pressure forming, two-piece forming or drape forming require different machines. The production capacity of thermoforming machines can vary from a few hundred to several thousand finished parts per hour. To select the appropriate thermoforming equipment, the following product specifications should be considered:

Molding Zone: The molding zone refers to the build space where the plastic pattern or design is formed. The forming area is equipped with designed molds, core plugs or mechanisms to apply patterns to preheated plastic sheets.

Draw Depth: Draw depth or draw ratio is critical to understanding the thermoforming process. Draw ratios let manufacturers know the plastic specifications required for each thermoforming project. The knowledge of "deep drawing" used by the equipment allows manufacturers to determine the thickness of the plastic part and the surface area that the plastic sheet should cover during the thermoforming process.

Machine Size: The size of the thermoforming equipment determines the size of the part or plastic part that can be produced by the selected equipment. Bench-top thermoforming equipment is compact and therefore limited in form size, whereas industrial solutions are much larger.

Clamping force: Some thermoforming machines, such as pressure forming, double sheeting and matching mold forming equipment, clamp the plastic sheet down to form the finished product. Clamping force is an important consideration as it helps determine the type of material that can be used.

Tool change capability: Evaluating the tool change capability of a thermoformer can help manufacturers determine how quickly a tool change can be performed. Faster tool changes increase the efficiency and cost-effectiveness of production facilities.

Heating System: Most thermoforming machines have two basic types of heating systems: reel and sheet. Roll-to-roll thermoformers are more expensive and can use infrared heating. Heating wires and resistance rods are common thermoforming heat sources, but they are not as efficient as quartz heaters. Heating wires and resistance rods are less expensive options, but less effective. Quartz heaters are more efficient, and most thermoformer manufacturers use thermistors or thermocouple-based controllers to regulate temperature.

Once the characteristics are known, the manufacturer can choose a thermoforming machine that falls into one of the following categories:

These are large machines built for medium to high volume production. Industrial vacuum formers are compatible with a wider range of materials and sheet thicknesses, provide deeper suction, and have stronger vacuum force or pressure to form intricate and intricate details and achieve part quality similar to injection molding. The cost of industrial thermoforming equipment starts at around $10,000 and goes way beyond that.

Bench-top thermoforming machines are smaller in size, with smaller material options and less force. They always use desktop thermoforming equipment for prototyping, custom parts and low-volume production. Tabletop thermoforming equipment starts under $1,000 and offers a variety of options for under $10,000.

Hobbyists who intend to try thermoforming can choose to make their own DIY equipment for small batch production. DIY equipment is generally more affordable than standard thermoforming equipment, but is more labor-intensive and requires specialized knowledge.

If you want to learn about thermoforming molds, look here.

Thermoforming uses plastic to make a variety of products. The most common thermoforming materials are high density polyethylene, HDPE and PET. These plastics are durable, chemically resistant, and have a high strength-to-density ratio. Here we will explain what thermoforming materials are.

This is a common material with good stiffness and impact strength. It comes in almost any color and several textures and can produce electrical enclosures, food containers and household appliances.

Properties of PMMA include high strength, weather resistance, durability and transparency. The durability of PMMA ensures that the end-use part will serve its purpose for a long time. It can be easily manufactured and is available in a variety of colors for lenses, vehicle headlights and clear packaging.

This material is both impact and chemical resistant. It also has very good low temperature properties. However, it is not as stable as many other available materials and can be used to make packaging films, blown bottles, containers, pipes and plastic bags. .

LDPE is resistant to chemicals and UV rays. Manufacturers can utilize LDPE to make packaging films, DVDs, cable insulation, containers and chemical resistant items.

This material is inexpensive. IT is also easy to form and available in a variety of colors. It is more brittle than some other materials, and polystyrene is widely used as a thermoforming packaging material because of its resistance to water and air, and is used to make food packaging, jewelry boxes, CD cases, and household items.

This material has high impact strength, chemical resistance and puncture resistance. It is ideal for medical joint replacements, recreational skis and bottles.

Polycarbonate is a strong, tough material that can withstand large impacts without cracking or breaking. They are heat-resistant, flame-retardant, and have good electrical insulating properties. PCs are used in eyeglasses, medical equipment, automotive parts, plastic lenses in protective gear, and automotive headlamps.

PET offers very good alcohol and essential oil barrier properties, good chemical resistance, and high impact and tensile strength. This material is commonly used in carbonated beverages, water bottles and many food packaging

This material is transparent and has excellent impact strength. It also forms well. Medical grade materials are available upon request.

PP is the most popular thermoforming plastic material in terms of value and volume. This material has excellent chemical resistance and is economical. It performs well at higher temperatures, but is not as dimensionally stable as other materials. It is commonly used to make packaging, ventilators, toys and other plastic products.

This rigid material is strong and has good impact strength and is used in the manufacture of pipes, window frames, automotive interiors, household items, packaging and footwear

This material has excellent impact properties. It is available in a high-gloss finish. It is suitable for outdoor applications. However, it is difficult to form, especially for applications that require deep drawn shapes.

Sheet Molding Compound, a fiberglass-reinforced plastic. The main raw materials are GF (special yarn), UP (unsaturated resin), MD (filler) and various low shrinkage additives and auxiliaries

It is made of resins (such as unsaturated polyesters, epoxy resins, phenolic resins, etc.), glass fibers, fillers and other additives. It can be adjusted by changing the added material according to the desired properties. It is usually striped to facilitate shaping and is widely used in many industrial fields.

Many uses are available for thermoforming. One of the most common is packaging, especially rigid packaging for food and consumer products, but it has many other applications. Because sheets of different thicknesses can be used, the technique is equally suitable for making toys, but also for building permanent surfaces on cars. So you can also see two other categories of thermoforming: thin and thick. Thin gauge thermoforming is most commonly used for disposable cups, lids, trays, blisters, and flip caps. Thick gauge thermoforming is used to make appliances, utility lathes and plastic pallets.

The thermoforming process can also be used for a variety of applications.

Contact US

Email: master@zjmdc.com

Tel: +86 576 84616076

Fax: +86 576 84616079

Mobile: +86 13906573507(Mr. Wang)

Address: No.116 mochuang road, Huangyan Xinqian street,Taizhou,Zhejiang,China